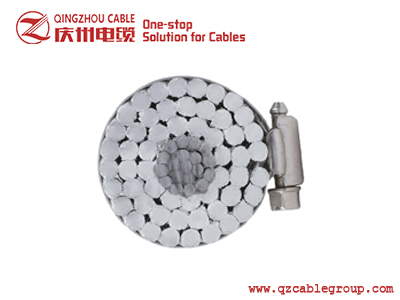

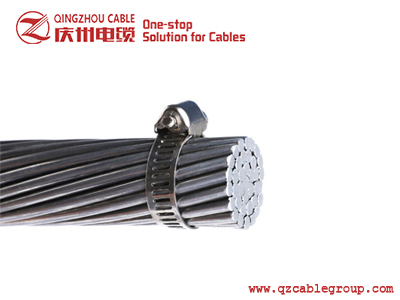

ACAR Conductor IEC 61089

Henan Qingzhou cable group is a professional aluminum cable manufacturer from China, Meet your kinds of requirement aluminum wire cable With over 26 years production experience and 10 years export experience, factory price without any third party.

Application

The aluminum conductor alloy reinforced(ACAR) is an excellent conductor choice where current carrying capacity, higher strength and a lower conductor weight are critical to the line design. The DC resistance of ACAR is smaller than ACSR, and the Aluminum Conductor Aluminum Alloy Reinforced can be avoided due to the loss of 152 * 104 (a – kW) / (H – 100km), with positive significance for transmission line energy saving. It is mainly used for electric distribution lines with little span, less stress. It has high current carrying capacity and good corrosion performance.

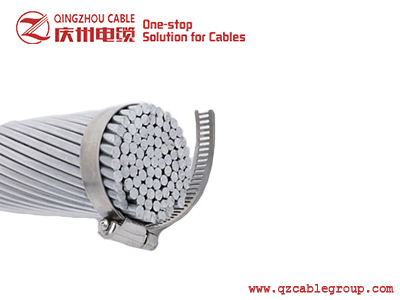

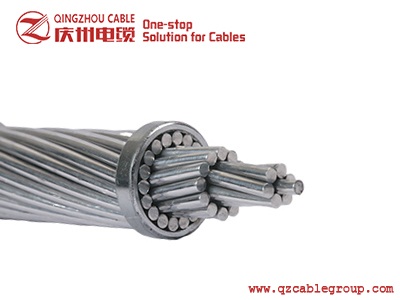

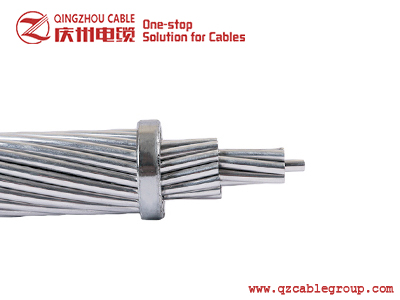

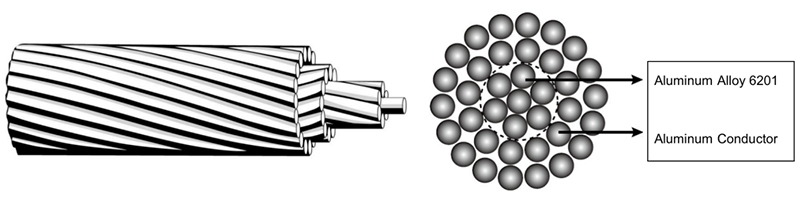

Structure

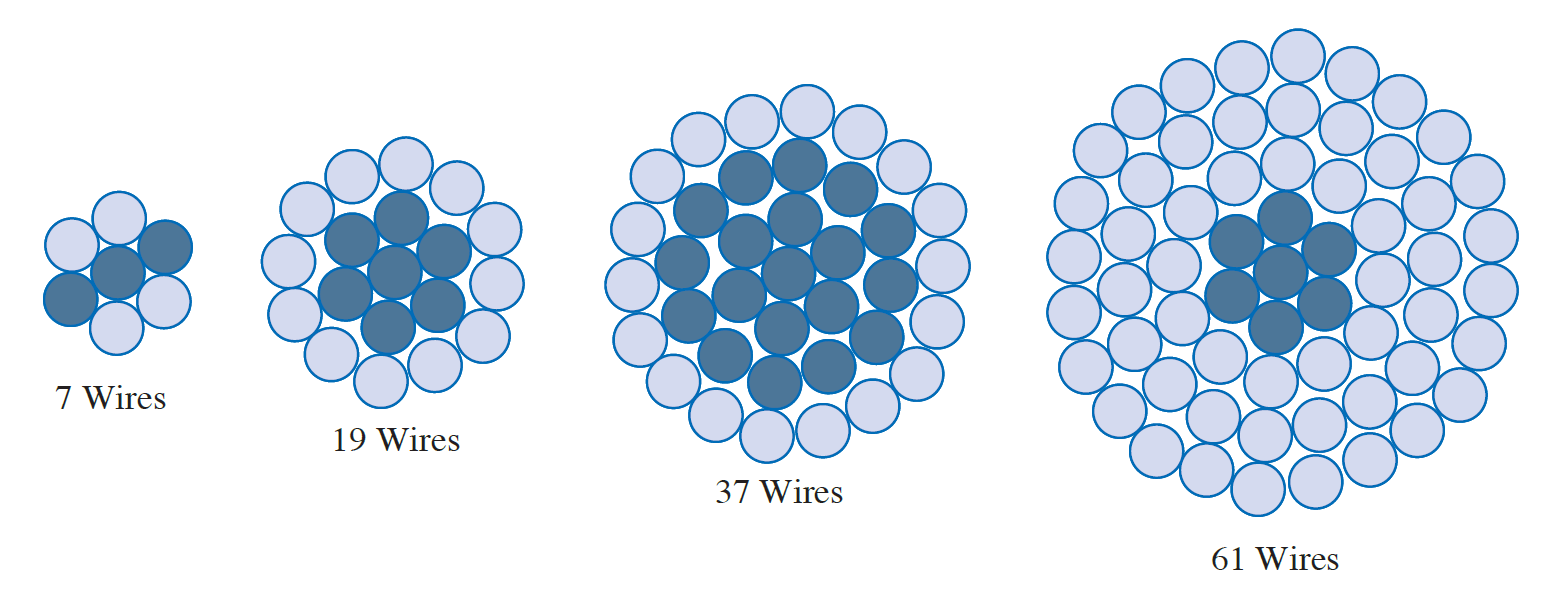

The aluminum conductor alloy reinforced(ACAR) has concentrically stranded aluminum 1350-H19 wire around a 6201-T81 aluminum alloy core. Typically, the 6201-T81 is the conductor core, but in certain designs, the 1350 H19 and the 6201-T81 wires may be stranded in the same layer.

|

Code Number |

Diameter |

No. of Wires |

Area |

Linear Mass |

Rated Strength |

D.C. Resistance at 20℃ |

||||

|

Wire |

Cond |

Alum. |

Alloy |

Alum. |

Alloy |

Total |

||||

|

mm |

mm |

mm2 |

mm2 |

mm2 |

kg/km |

kN |

ohm/km |

|||

|

IEC61089 A1/A2 |

||||||||||

|

16 |

1.76 |

5.28 |

4 |

3 |

9.73 |

7.3 |

17 |

46.6 |

3.85 |

1.7896 |

|

25 |

2.2 |

6.6 |

4 |

3 |

15.2 |

11.4 |

26.6 |

72.8 |

5.93 |

1.1453 |

|

40 |

2.78 |

8.35 |

4 |

3 |

24.3 |

18.3 |

42.6 |

116.5 |

9.25 |

0.7158 |

|

63 |

3.49 |

10.5 |

4 |

3 |

38.3 |

28.7 |

67.1 |

183.5 |

14.38 |

0.4545 |

|

100 |

4.4 |

13.2 |

4 |

3 |

60.8 |

45.6 |

106 |

291.2 |

22.52 |

0.2863 |

|

125 |

2.97 |

14.9 |

12 |

7 |

83.3 |

48.6 |

132 |

362.7 |

27.79 |

0.2302 |

|

160 |

3.36 |

16.8 |

12 |

7 |

107 |

62.2 |

169 |

464.2 |

35.04 |

0.1798 |

|

200 |

3.76 |

18.8 |

12 |

7 |

133 |

77.8 |

211 |

580.3 |

43.13 |

0.1439 |

|

250 |

4.21 |

21 |

12 |

7 |

167 |

97.2 |

264 |

725.3 |

53.92 |

0.1151 |

|

250 |

3.04 |

21.3 |

18 |

19 |

131 |

138 |

269 |

742.2 |

60.39 |

0.1154 |

|

315 |

3.34 |

23.4 |

30 |

7 |

263 |

61.3 |

324 |

892.6 |

60.52 |

0.0916 |

|

315 |

3.42 |

23.9 |

18 |

19 |

165 |

174 |

339 |

935.1 |

76.09 |

0.0916 |

|

400 |

3.76 |

26.3 |

30 |

7 |

334 |

77.8 |

411 |

1133.5 |

75.19 |

0.0721 |

|

400 |

3.85 |

27 |

18 |

19 |

210 |

221 |

431 |

1187.5 |

95.58 |

0.0721 |

|

450 |

3.99 |

27.9 |

30 |

7 |

375 |

87.6 |

463 |

1275.2 |

84.59 |

0.0641 |

|

450 |

4.08 |

28.6 |

18 |

19 |

236 |

249 |

485 |

1335.9 |

107.52 |

0.0641 |

|

500 |

4.21 |

29.4 |

30 |

7 |

417 |

97.3 |

514 |

1416.9 |

93.98 |

0.0577 |

|

500 |

4.31 |

30.1 |

18 |

19 |

262 |

277 |

539 |

1484.3 |

119.47 |

0.0577 |

|

560 |

4.45 |

31.2 |

30 |

7 |

467 |

109 |

576 |

1586.9 |

105.26 |

0.0515 |

|

560 |

3.45 |

31 |

54 |

7 |

504 |

65.4 |

570 |

1571.9 |

101.54 |

0.0516 |

|

630 |

3.79 |

34.1 |

24 |

37 |

271 |

417 |

688 |

1897.5 |

160.19 |

0.0458 |

|

710 |

3.94 |

35.5 |

42 |

19 |

512 |

232 |

743 |

2051.2 |

146.78 |

0.0407 |

|

710 |

4.02 |

36.2 |

24 |

37 |

305 |

470 |

775 |

2138.4 |

180.53 |

0.0407 |

|

800 |

4.18 |

37.6 |

42 |

19 |

577 |

261 |

838 |

2311.2 |

162.39 |

0.0361 |

|

800 |

4.27 |

38.4 |

24 |

37 |

344 |

530 |

873 |

2409.5 |

203.41 |

0.0361 |

|

900 |

4.43 |

39.9 |

42 |

19 |

649 |

294 |

942 |

2600.1 |

186.06 |

0.0321 |

|

900 |

3.66 |

40.2 |

54 |

37 |

567 |

388 |

955 |

2638.4 |

199.54 |

0.0321 |

|

1000 |

3.8 |

41.8 |

72 |

19 |

816 |

215 |

1032 |

2849.1 |

190.94 |

0.0289 |

|

1000 |

3.85 |

42.4 |

54 |

37 |

630 |

432 |

1061 |

2931.6 |

221.71 |

0.0289 |

|

1120 |

4.02 |

44.2 |

72 |

19 |

914 |

241 |

1155 |

3191 |

213.85 |

0.0258 |

|

1120 |

4.08 |

44.9 |

54 |

37 |

705 |

483 |

1189 |

3283.4 |

248.32 |

0.0258 |

|

1250 |

4.25 |

46.7 |

72 |

19 |

1020 |

269 |

1289 |

3561.4 |

238.68 |

0.0231 |

|

1250 |

4.31 |

47.4 |

54 |

37 |

787 |

539 |

1327 |

3664.5 |

277.14 |

0.0231 |

|

1400 |

4.5 |

49.4 |

72 |

19 |

1143 |

302 |

1444 |

3988.8 |

267.32 |

0.0207 |

|

Code Number |

Diameter |

No. of Wires |

Area |

Linear Mass |

Rated Strength |

D.C. Resistance at 20℃ |

||||

|

|

Wire |

Cond |

Alum. |

Alloy |

Alum. |

Alloy |

Total |

|

|

|

|

|

mm |

mm |

|

|

mm2 |

mm2 |

mm2 |

kg/km |

kN |

ohm/km |

|

IEC61089 A1/A3 |

||||||||||

|

16 |

1.76 |

5.29 |

4 |

3 |

9.78 |

7.33 |

17.1 |

46.8 |

4.07 |

1.7896 |

|

25 |

2.21 |

6.62 |

4 |

3 |

15.3 |

11.5 |

26.7 |

73.1 |

6.29 |

1.1453 |

|

40 |

2.79 |

8.37 |

4 |

3 |

24.4 |

18.3 |

42.8 |

117 |

9.82 |

0.7158 |

|

63 |

3.5 |

10.5 |

4 |

3 |

38.5 |

28.9 |

67.4 |

184.3 |

14.8 |

0.4545 |

|

100 |

4.41 |

13.2 |

4 |

3 |

61.1 |

45.8 |

107 |

292.5 |

23.49 |

0.2863 |

|

125 |

2.98 |

14.9 |

12 |

7 |

83.7 |

48.8 |

132 |

364.1 |

29.29 |

0.2302 |

|

160 |

3.37 |

16.8 |

12 |

7 |

107 |

62.5 |

170 |

466 |

36.95 |

0.1798 |

|

200 |

3.77 |

18.8 |

12 |

7 |

134 |

78.1 |

212 |

582.5 |

44.78 |

0.1439 |

|

250 |

4.21 |

21.1 |

12 |

7 |

167 |

97.6 |

265 |

728.1 |

55.98 |

0.1151 |

|

250 |

3.05 |

21.4 |

18 |

19 |

132 |

139 |

271 |

746 |

64.67 |

0.1154 |

|

315 |

3.34 |

23.4 |

30 |

7 |

263 |

61.4 |

325 |

894.4 |

62.4 |

0.0916 |

|

315 |

3.43 |

24 |

18 |

19 |

166 |

175 |

341 |

940 |

81.48 |

0.0916 |

|

400 |

3.77 |

26.4 |

30 |

7 |

334 |

78 |

412 |

1135.8 |

76.82 |

0.0721 |

|

400 |

3.86 |

27 |

18 |

19 |

211 |

222 |

433 |

1193.7 |

100.3 |

0.0721 |

|

450 |

3.99 |

28 |

30 |

7 |

376 |

87.7 |

464 |

1277.8 |

86.42 |

0.0641 |

|

450 |

4.1 |

28.7 |

18 |

19 |

237 |

250 |

487 |

1342.9 |

112.84 |

0.0641 |

|

500 |

4.21 |

29.5 |

30 |

7 |

418 |

97.5 |

515 |

1419.8 |

96.03 |

0.0577 |

|

500 |

4.32 |

30.2 |

18 |

19 |

263 |

278 |

542 |

1492.1 |

125.38 |

0.0577 |

|

560 |

4.46 |

31.2 |

30 |

7 |

468 |

109 |

577 |

1590.1 |

107.55 |

0.0515 |

|

560 |

3.45 |

31.1 |

54 |

7 |

505 |

65.5 |

570 |

1573.9 |

103.53 |

0.0516 |

|

630 |

3.72 |

33.4 |

42 |

19 |

456 |

206 |

662 |

1826 |

134.59 |

0.0458 |

|

630 |

3.8 |

34.2 |

24 |

37 |

272 |

420 |

692 |

1909 |

169.14 |

0.0458 |

|

710 |

3.95 |

35.5 |

42 |

19 |

514 |

232 |

746 |

2057.8 |

151.68 |

0.0407 |

|

710 |

4.03 |

36.3 |

24 |

37 |

307 |

473 |

780 |

2151.4 |

190.61 |

0.0407 |

|

800 |

4.19 |

37.7 |

42 |

19 |

579 |

262 |

840 |

2318.7 |

170.9 |

0.0361 |

|

800 |

4.28 |

38.5 |

24 |

37 |

346 |

533 |

879 |

2424.2 |

214.78 |

0.0361 |

|

900 |

4.44 |

40 |

42 |

19 |

651 |

294 |

945 |

2608.5 |

192.27 |

0.0321 |

|

900 |

3.66 |

40.3 |

54 |

37 |

569 |

390 |

959 |

2649.5 |

207.79 |

0.0321 |

|

1000 |

3.8 |

41.8 |

72 |

19 |

818 |

216 |

1034 |

2855.4 |

195.47 |

0.0289 |

|

1000 |

3.86 |

42.5 |

54 |

37 |

632 |

433 |

1066 |

2943.9 |

230.88 |

0.0289 |

|

1120 |

4.02 |

44.3 |

72 |

19 |

916 |

242 |

1158 |

3198.1 |

218.92 |

0.0258 |

|

1120 |

4.09 |

45 |

54 |

37 |

708 |

485 |

1194 |

3297.2 |

258.58 |

0.0258 |

|

1250 |

4.25 |

46.8 |

72 |

19 |

1022 |

270 |

1292 |

3569.3 |

244.33 |

0.0231 |

|

1250 |

4.32 |

47.5 |

54 |

37 |

791 |

542 |

1332 |

3679.9 |

288.6 |

0.0231 |

|

1400 |

4.5 |

49.5 |

72 |

19 |

1145 |

302 |

1447 |

3997.6 |

273.65 |

0.0207 |

If you need other ACAR standard, we can manufacture them according to your request.

Get a free quote by e-mail: info@qzcablegroup.com

Our Products

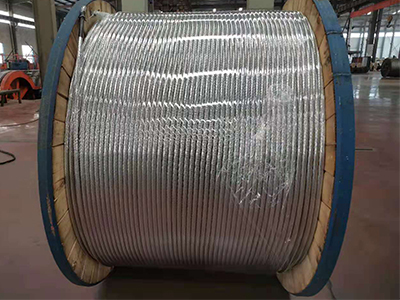

Our Factory

Why you choose us as your gold supplier?

♦ Your inquiry will be replied to within the hour.

♦ Your label design according to your requirements ready in 2 days.

♦ 26 years OEM/ODM experience.

♦ Goods are sold with rerun or refund guarantee due to quality issue.

♦ Prompt shipment by reputed shipping line and professional documents.

♦ Cargoes photo before and after loading into container after shipment with e-mail.