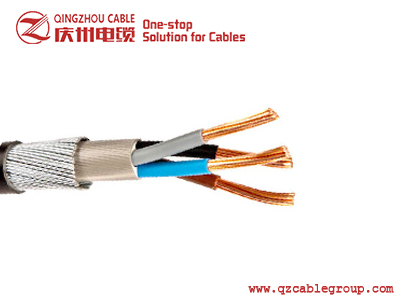

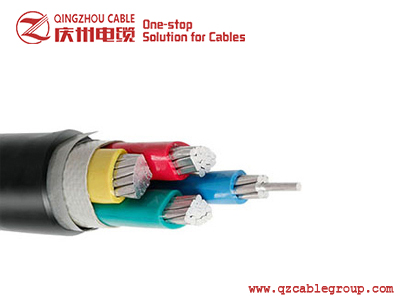

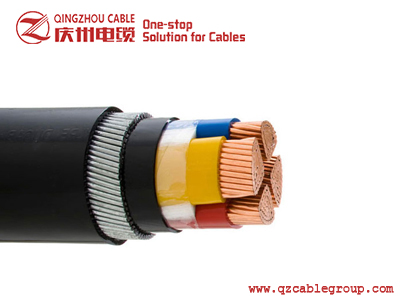

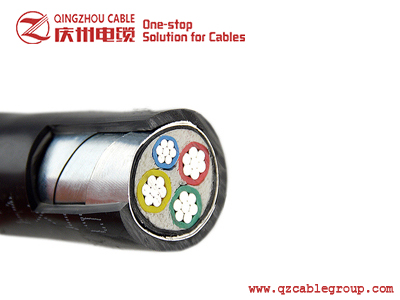

Armoured Cable SWA & AWA

Applications :

Armoured cable is available with a Copper (Cu) or Aluminium (Al) conductor and with a Polyvinyl Chloride (PVC) or Low Smoke Zero Halogen (LSZH) sheathing, LSZH sheathings are recommended for use in high density enclosed areas, and are mandatory in some public places.

These cables include low voltage and medium voltage SWA steel wire armour 3 core cable, and all sizes of these widely used armoured power cables with current ratings up to 33kV. For single core cables, aluminium wire armour – AWA – is used to prevent induced current in the armour. Armoured power cables are available with both copper and aluminium conductors as required. The cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside buildings or for direct burial in the ground.

Construction :

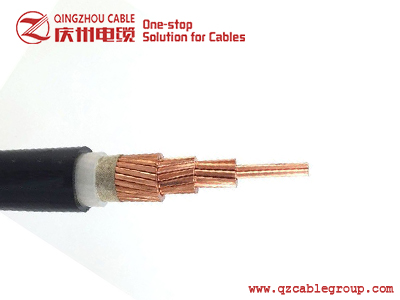

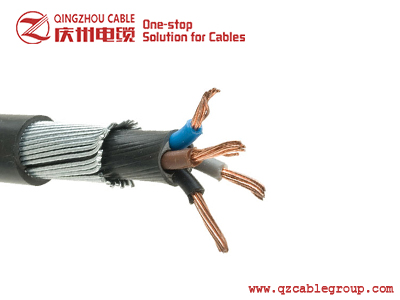

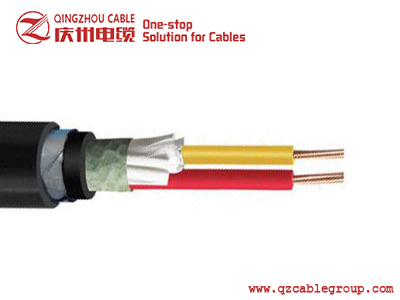

Conductor: plain stranded copper or aluminium

Insulation: materials such as cross-linked polyethylene (XLPE) provide high temperature resistance and excellent dielectric strength-providing enhanced electrical properties.

Bedding: a layer to create a protective barrier between the insulation and the armour.

Armour: a steel or aluminium armour provides mechanical protection to allow the cable to withstand the mechanical stresses to which it is exposed.

Sheath: the constituent parts of the cable are held together by a sheath offering a further level of protection. Black sheaths can be carbon-loaded for UV stability.

Voltage: voltage ratings of 600/1000V, 6.35/11kV and 19/33kV.

Construction

|

Conductor |

Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, IEC 60228. |

|

Insulation |

XLPE (Cross-Linked Polyethylene) Type GP 8 or ethylene propylene rubber (GP 6) |

|

Colour Code |

1 Core : Brown |

|

2 Cores: Brown or Blue |

|

|

3 Cores: Brown, Black, Grey |

|

|

4 Cores: Blue, Brown, Black, Grey |

|

|

5 Cores: Green/Yellow, Blue, Brown, Black, Grey |

|

|

Above 5 Cores: White Cores with black numbers |

|

|

Bedding |

PVC (Polyvinyl Chloride) |

|

Armour |

Single Core: AWA (Aluminum Wire Armour) |

|

Multi Core: SWA (Steel Wire Armour) |

|

|

Outer Sheath |

PVC(Polyvinyl Chloride) |

Technical Information :

|

Voltage rating |

600/1000V, 1900/3300V, 3.6/6(7.2)kV, 3.8/6.6(7.2)kV, 6/10(12)kV,6.35/11(12)kV, 8.7/10(15)kV, 8.7/15(17.5)kV, 12/20(22)kV,12.7/22(24)kV, 12.7/22(24)kV,18/30(36)kV, 19/33(36)kV |

|

Temperature rating |

0°C to +90°C |

|

Bending radius |

1.5mm² to 16mm² : 6 x overall diameter |

|

25mm² and above : 8 x overall diameter |

|

|

Flame retardant |

IEC60332 part 1, BS4066 part 1 |

XLPE insulated Armored Power Cable

|

0.6/1kV XLPE Insulated Unarmoured/Armoured Cable |

Core |

Armor |

|

Cu or Al/XLPE/PVC Power Cable |

Single Core |

No |

|

Cu or Al/XLPE/AWA/PVC Power Cable |

Single Core |

AWA |

|

Cu or Al/XLPE/PVC Power Cable |

Two Cores |

No |

|

Cu or Al/XLPE/STA/PVC Power Cable |

Two Cores |

STA |

|

Cu or Al/XLPE/SWA/PVC Power Cable |

Two Cores |

SWA |

|

Cu or Al/XLPE/PVC Power Cable |

Three Cores |

No |

|

Cu or Al/XLPE/STA/PVC Power Cable |

Three Cores |

STA |

|

Cu or Al/XLPE/SWA/PVC Power Cable |

Three Cores |

SWA |

|

Cu or Al/XLPE/PVC Power Cable |

3+1 Cores |

No |

|

Cu or Al/XLPE/STA/PVC Power Cable |

3+1 Cores |

STA |

|

Cu or Al/XLPE/SWA/PVC Power Cable |

3+1 Cores |

SWA |

|

Cu or Al/XLPE/PVC Power Cable |

Four Cores |

No |

|

Cu or Al/XLPE/STA/PVC Power Cable |

Four Cores |

STA |

|

Cu or Al/XLPE/SWA/PVC Power Cable |

Four Cores |

SWA |

|

Cu or Al/XLPE/PVC Power Cable |

4+1 Cores |

No |

|

Cu or Al/XLPE/STA/PVC Power Cable |

4+1 Cores |

STA |

|

Cu or Al/XLPE/SWA/PVC Power Cable |

4+1 Cores |

SWA |

|

Cu or Al/XLPE/PVC Power Cable |

Five Cores |

No |

|

Cu or Al/XLPE/STA/PVC Power Cable |

Five Cores |

STA |

|

Cu or Al/XLPE/SWA/PVC Power Cable |

Five Cores |

SWA |

|

Cu or Al/XLPE/PVC Power Cable |

3+2 Cores |

No |

|

Cu or Al/XLPE/STA/PVC Power Cable |

3+2 Cores |

STA |

|

Cu or Al/XLPE/SWA/PVC Power Cable |

3+2 Cores |

SWA |

PVC insulated Armored Power Cable

|

0.6/1kV PVC Insulated Cable |

Conductor |

Insulation |

Armor |

Outer Sheath |

|||||

|

Aluminum |

Copper |

PVC |

SW |

ST |

DST |

AW |

PVC |

PE |

|

|

Cu/PVC/PVC |

|

P |

P |

— |

— |

— |

— |

P |

|

|

Cu/PVC/PE |

|

P |

P |

— |

— |

— |

— |

|

P |

|

Al/PVC/PVC |

P |

|

P |

— |

— |

— |

— |

P |

|

|

Al/PVC/PE |

P |

|

P |

— |

— |

— |

— |

|

P |

|

Cu/PVC/STA/PVC |

|

P |

P |

— |

P |

— |

— |

P |

|

|

Cu/PVC/STA/PE |

|

P |

P |

— |

P |

— |

— |

|

P |

|

Al/PVC/STA/PVC |

P |

|

P |

— |

P |

— |

— |

P |

|

|

Al/PVC/STA/PE |

P |

|

P |

— |

P |

— |

— |

|

P |

|

Cu/PVC/DSTA/PVC |

|

P |

P |

— |

— |

P |

— |

P |

|

|

Cu/PVC/DSTA/PE |

|

P |

P |

— |

— |

P |

— |

|

P |

|

Al/PVC/DSTA/PVC |

P |

|

P |

— |

— |

P |

— |

P |

|

|

Al/PVC/DSTA/PE |

P |

|

P |

— |

— |

P |

— |

|

P |

|

Cu/PVC/SWA/PVC |

|

P |

P |

P |

— |

— |

— |

P |

|

|

Cu/PVC/SWA/PE |

|

P |

P |

P |

— |

— |

— |

|

P |

|

Al/PVC/SWA/PVC |

P |

|

P |

P |

— |

— |

— |

P |

|

|

Al/PVC/SWA/PE |

P |

|

P |

P |

— |

— |

— |

|

P |

|

Cu/PVC/AWA/PVC |

|

P |

P |

— |

— |

— |

P |

P |

|

|

Cu/PVC/AWA/PE |

|

P |

P |

— |

— |

— |

P |

|

P |

|

Al/PVC/AWA/PVC |

P |

|

P |

— |

— |

— |

P |

P |

|

|

Al/PVC/AWA/PE |

P |

|

P |

— |

— |

— |

P |

|

P |

|

Armor material : SW=steel wire, ST=steel tape, DST=double steel tape, AW=aluminum wire |

|||||||||

Single-core 600/1000V cables with circular stranded copper conductor

|

Nominal Cross-sectional Area |

Strand Type |

Nominal Insulation thickness |

Nominal Bedding thickness |

Nominal Alum Wire dia. |

Nominal Sheath thickness |

Approx.Overall Diameter |

Aprrox |

|

mm² |

No./mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

1×50 |

19/1.78 |

1.0 |

0.8 |

0.9 |

1.5 |

17.5 |

800 |

|

1×70 |

19/2.14 |

1.1 |

0.8 |

1.25 |

1.5 |

20.2 |

990 |

|

1×95 |

19/2.52 |

1.1 |

0.8 |

1.25 |

1.6 |

22.3 |

1280 |

|

1×120 |

37/2.03 |

1.2 |

0.8 |

1.25 |

1.6 |

24.2 |

1550 |

|

1×150 |

37/2.25 |

1.4 |

1 |

1.6 |

1.7 |

27.4 |

1900 |

|

1×185 |

37/2.52 |

1.6 |

1 |

1.6 |

1.8 |

30.0 |

2320 |

|

1×240 |

61/2.25 |

1.7 |

1 |

1.6 |

1.8 |

32.8 |

2930 |

|

1×300 |

61/2.52 |

1.8 |

1 |

1.6 |

1.9 |

35.6 |

3580 |

|

1×400 |

61/2.85 |

2.0 |

1.2 |

2.0 |

2.0 |

40.5 |

4600 |

|

1×500 |

61/3.20 |

2.2 |

1.2 |

2.0 |

2.1 |

44.2 |

5680 |

|

1×630 |

127/2.52 |

2.4 |

1.2 |

2.0 |

2.2 |

48.8 |

7160 |

|

1×800 |

127/2.85 |

2.6 |

1.4 |

2.5 |

2.4 |

55.4 |

9315 |

|

1×1000 |

127/3.20 |

2.8 |

1.4 |

2.5 |

2.5 |

60.6 |

11490 |

Single-core 600/1000V cables with solid aluminum conductor

|

Nominal Cross-sectional Area |

Nominal Insulation thickness |

Nominal Bedding thickness |

Nominal Alum Wire Armor dia. |

Armour strip |

Nominal Sheath thickness |

Approx.Overall Diameter |

Aprrox Weight |

||

|

thickness |

width |

wire armor |

strip armor |

||||||

|

mm² |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

1×50 |

1.0 |

0.8 |

0.9 |

0.6 |

2.4 |

1.5 |

16.3 |

15.7 |

460 |

|

1×70 |

1.1 |

0.8 |

1.25 |

0.6 |

2.4 |

1.5 |

18.7 |

17.4 |

560 |

|

1×95 |

1.1 |

0.8 |

1.25 |

0.6 |

2.4 |

1.6 |

20.6 |

19.3 |

690 |

|

1×120 |

1.2 |

0.8 |

1.25 |

0.6 |

2.4 |

1.6 |

22.1 |

20.8 |

800 |

|

1×150 |

1.4 |

1 |

1.6 |

0.6 |

2.4 |

1.7 |

25.2 |

23.2 |

970 |

|

1×185 |

1.6 |

1 |

1.6 |

0.6 |

2.4 |

1.8 |

27.4 |

25.4 |

1150 |

|

1×240 |

1.7 |

1 |

1.6 |

1 |

3.6 |

1.8 |

29.9 |

28.7 |

1380 |

|

1×300 |

1.8 |

1 |

1.6 |

1 |

3.6 |

1.9 |

32.4 |

31.2 |

1640 |

Two-core 600/1000V cables with stranded copper conductors

|

Nominal Cross-sectional Area |

Strand Type |

Nominal Insulation thick-ness |

Nominal Bedding thickness |

Nominal Steel Wire Armor dia. |

Nominal Sheath thickness |

Approx. Overall Diameter |

Aprrox Weight |

|

|

Extruded bedding |

Taped bedding |

|||||||

|

mm² |

No./mm |

mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

2×1.5 |

7/0.53 |

0.6 |

0.8 |

0.9 |

1.4 |

12.1 |

– |

320 |

|

2×2.5 |

7/0.67 |

0.7 |

0.8 |

0.9 |

1.4 |

13.6 |

– |

365 |

|

2×4 |

7/0.85 |

0.7 |

0.8 |

0.9 |

1.4 |

14.7 |

– |

440 |

|

2×6 |

7/1.04 |

0.7 |

0.8 |

0.9 |

1.4 |

15.9 |

– |

470 |

|

2×10 |

7/1.35 |

0.7 |

0.8 |

0.9 |

1.5 |

18.0 |

– |

800 |

|

2×16 |

7/1.70 |

0.7 |

0.8 |

1.25 |

1.5 |

20.4 |

20.4 |

900 |

|

2×25 |

7/2.14 |

0.9 |

0.8 |

1.25 |

1.6 |

24.1 |

24.1 |

1240 |

|

2×25* |

7/2.14 |

0.9 |

0.8 |

1.25 |

1.6 |

20.4 |

20.4 |

1240 |

|

2×35 |

7/2.52 |

0.9 |

1 |

1.6 |

1.7 |

27.7 |

27.3 |

1710 |

|

2×35* |

7/2.52 |

0.9 |

1 |

1.6 |

1.7 |

23.3 |

22.9 |

1710 |

|

2×50* |

19/1.78 |

1.0 |

1 |

1.6 |

1.8 |

25.8 |

25.4 |

1800 |

|

2×70* |

19/2.14 |

1.1 |

1 |

1.6 |

1.9 |

29.0 |

28.6 |

2320 |

|

2×95* |

19/2.52 |

1.1 |

1.2 |

2.0 |

2.0 |

33.1 |

32.3 |

3150 |

|

2×120* |

37/2.03 |

1.2 |

1.2 |

2.0 |

2.1 |

36.1 |

35.3 |

3880 |

|

2×150* |

37/2.25 |

1.4 |

1.2 |

2.0 |

2.2 |

39.3 |

38.5 |

4820 |

|

2×185* |

37/2.52 |

1.6 |

1.4 |

2.5 |

2.4 |

44.7 |

43.5 |

5920 |

|

2×240* |

61/2.25 |

1.7 |

1.4 |

2.5 |

2.5 |

49.0 |

47.8 |

7300 |

|

2×300* |

61/2.52 |

1.8 |

1.6 |

2.5 |

2.6 |

53.5 |

51.9 |

8770 |

|

2×400* |

61/2.85 |

2 |

1.6 |

2.5 |

2.8 |

59.0 |

57.4 |

10905 |

* D-Shaped stranded conductor (class 2)

Two-core 600/1000V cables with solid aluminum conductors

|

Nominal Cross-sectional Area |

Nominal Insulation thickness |

Nominal Bedding thickness |

Nominal Steel Wire Armor dia. |

Armour strip |

Nominal Sheath thickness |

Approx. Overall Diameter |

Aprrox Weight |

|||

|

thick-ness |

width |

wire armor |

strip armor |

|||||||

|

Extruded bedding |

Taped bedding |

|||||||||

|

mm² |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

2×16 |

0.7 |

0.8 |

1.25 |

0.6 |

2.4 |

1.5 |

19.1 |

19.1 |

17.8 |

650 |

|

2×25 |

0.9 |

0.8 |

1.25 |

0.6 |

2.4 |

1.5 |

22.4 |

22.4 |

21.1 |

915 |

|

2×25* |

0.9 |

0.8 |

1.25 |

0.6 |

2.4 |

1.6 |

18.7 |

18.7 |

17.4 |

1255 |

|

2×35 |

0.9 |

1 |

1.6 |

0.6 |

2.4 |

1.6 |

25.7 |

25.3 |

23.3 |

1255 |

|

2×35* |

0.9 |

1 |

1.6 |

0.6 |

2.4 |

1.7 |

21.4 |

21.0 |

19 |

1430 |

|

2×50* |

1.0 |

1 |

1.6 |

0.6 |

2.4 |

1.8 |

23.5 |

23.1 |

21.1 |

1430 |

|

2×70* |

1.1 |

1 |

1.6 |

1 |

3.6 |

1.9 |

26.3 |

25.9 |

24.7 |

1780 |

|

2×95* |

1.1 |

1.2 |

2.0 |

1 |

3.6 |

2 |

30 |

29.2 |

27.2 |

1950 |

*Solid shaped conductor (class 1)

Three-core 600/1000V cables with stranded copper conductors

|

Nominal Cross-sectional Area |

Strand Type |

Nominal Insulation thickness |

Nominal Bedding thickness |

Nominal Steel Wire Armor dia. |

Nominal Sheath thickness |

Approx. Overall Diameter |

Aprrox |

|

|

Extruded bedding |

Taped bedding |

|||||||

|

mm² |

No./mm |

mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

3×1.5 |

7/0.53 |

0.6 |

0.8 |

0.9 |

1.3 |

12.6 |

– |

340 |

|

3×2.5 |

7/0.67 |

0.7 |

0.8 |

0.9 |

1.4 |

14.1 |

– |

408 |

|

3×4 |

7/0.85 |

0.7 |

0.8 |

0.9 |

1.4 |

15.3 |

– |

498 |

|

3×6 |

7/1.04 |

0.7 |

0.8 |

0.9 |

1.4 |

16.6 |

– |

600 |

|

3×10 |

7/1.35 |

0.7 |

0.8 |

1.25 |

1.5 |

19.5 |

– |

915 |

|

3×16 |

7/1.70 |

0.7 |

0.8 |

1.25 |

1.6 |

21.6 |

21.6 |

1130 |

|

3×25 |

7/2.14 |

0.9 |

1 |

1.6 |

1.7 |

26.7 |

26.3 |

1710 |

|

3×25* |

7/2.14 |

0.9 |

1 |

1.6 |

1.7 |

23.6 |

23.2 |

1710 |

|

3×35 |

7/2.52 |

0.9 |

1 |

1.6 |

1.8 |

29.4 |

29.0 |

2100 |

|

3×35* |

7/2.52 |

0.9 |

1 |

1.6 |

1.8 |

25.7 |

25.3 |

2100 |

|

3×50* |

19/1.78 |

1.0 |

1 |

1.6 |

1.8 |

28.5 |

28.1 |

2450 |

|

3×70* |

19/2.14 |

1.1 |

1 |

1.6 |

1.9 |

32.2 |

31.8 |

3120 |

|

3×95* |

19/2.52 |

1.1 |

1.2 |

2.0 |

2.1 |

37.0 |

36.2 |

4310 |

|

3×120* |

37/2.03 |

1.2 |

1.2 |

2.0 |

2.2 |

40.4 |

39.6 |

5160 |

|

3×150* |

37/2.25 |

1.4 |

1.4 |

2.5 |

2.3 |

45.5 |

44.3 |

7160 |

|

3×185* |

37/2.52 |

1.6 |

1.4 |

2.5 |

2.4 |

49.8 |

48.6 |

8600 |

|

3×240* |

61/2.25 |

1.7 |

1.4 |

2.5 |

2.6 |

55.1 |

53.9 |

10755 |

|

3×300* |

61/2.52 |

1.8 |

1.6 |

2.5 |

2.7 |

60.2 |

58.6 |

13080 |

|

3×400* |

61/2.85 |

2 |

1.6 |

2.5 |

2.9 |

66.6 |

65.0 |

15810 |

*Shaped stranded conductor (class 2)

Three-core 600/1000V cables with solid aluminum conductors

|

Nominal Cross-sectional Area |

Nominal Insulation thickness |

Nominal Bedding thickness |

Nominal Steel Wire Armor dia. |

Armour strip |

Nominal Sheath thickness |

Approx. Overall Diameter |

Aprrox Weight |

|||

|

thick-ness |

width |

wire armor |

strip armor |

|||||||

|

Extruded bedding |

Taped bedding |

|||||||||

|

mm² |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

3×16 |

0.7 |

0.8 |

1.25 |

0.6 |

2.4 |

1.6 |

20.3 |

20.3 |

19 |

760 |

|

3×25 |

0.9 |

1 |

1.6 |

0.6 |

2.4 |

1.7 |

22.5 |

22.1 |

20.1 |

1020 |

|

3×25* |

0.9 |

1 |

1.6 |

0.6 |

2.4 |

1.7 |

24.9 |

24.5 |

22.5 |

1020 |

|

3×35 |

0.9 |

1 |

1.6 |

0.6 |

2.4 |

1.8 |

24.4 |

24.9 |

22 |

1200 |

|

3×35* |

0.9 |

1 |

1.6 |

0.6 |

2.4 |

1.8 |

27.3 |

26.9 |

24.9 |

1200 |

|

3×50* |

1.0 |

1 |

1.6 |

0.6 |

2.4 |

1.8 |

26.8 |

26.4 |

24.9 |

1380 |

|

3×70* |

1.1 |

1 |

1.6 |

1 |

3.6 |

1.9 |

30.2 |

29.8 |

28.6 |

1750 |

|

3×95* |

1.1 |

1.2 |

2.0 |

1 |

3.6 |

2.1 |

34.8 |

34.0 |

32 |

2420 |

|

3×120* |

1.2 |

1.2 |

2.0 |

1.4 |

4.8 |

2.2 |

37.8 |

37.0 |

35.8 |

2820 |

|

3×150* |

1.4 |

1.4 |

2.5 |

1.4 |

4.8 |

2.3 |

42.7 |

41.5 |

39.3 |

3660 |

|

3×185* |

1.6 |

1.4 |

2.5 |

1.4 |

4.8 |

2.4 |

46.7 |

45.5 |

43.3 |

4350 |

|

3×240* |

1.7 |

1.4 |

2.5 |

1.4 |

4.8 |

2.6 |

51.5 |

50.3 |

48.1 |

5220 |

|

3×300* |

1.8 |

1.6 |

2.5 |

1.8 |

6.4 |

2.7 |

56.2 |

54.6 |

53.2 |

6200 |

Four-core 600/1000V cables with stranded copper conductors

|

Nominal Cross-sectional Area |

Strand Type |

Nominal Insulation thickness |

Nominal Bedding thickness |

Nominal Steel Wire Armor dia. |

Nominal Sheath thickness |

Approx. Overall Diameter |

Aprrox |

|

|

Extruded bedding |

Taped bedding |

|||||||

|

mm² |

No./mm |

mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

4×1.5 |

7/0.53 |

0.7 |

0.8 |

0.9 |

1.4 |

13.3 |

– |

390 |

|

4×2.5 |

7/0.67 |

0.7 |

0.8 |

0.9 |

1.4 |

15.0 |

– |

470 |

|

4×4 |

7/0.85 |

0.7 |

0.8 |

0.9 |

1.4 |

16.4 |

– |

580 |

|

4×6 |

7/1.04 |

0.7 |

0.8 |

1.25 |

1.5 |

18.7 |

– |

805 |

|

4×10 |

7/1.35 |

0.7 |

0.8 |

1.25 |

1.5 |

21.1 |

– |

1090 |

|

4×16 |

7/1.70 |

0.7 |

0.8 |

1.25 |

1.6 |

23.4 |

23.4 |

1320 |

|

4×25 |

7/2.14 |

0.9 |

1 |

1.6 |

1.7 |

28.9 |

28.5 |

1840 |

|

4×25* |

7/2.14 |

0.9 |

1 |

1.6 |

1.7 |

26.1 |

25.7 |

1840 |

|

4×35 |

7/2.52 |

0.9 |

1 |

1.6 |

1.8 |

31.9 |

31.5 |

2310 |

|

4×35* |

7/2.52 |

0.9 |

1 |

1.6 |

1.8 |

28.6 |

28.2 |

2310 |

|

4×50* |

19/1.78 |

1.0 |

1 |

1.6 |

1.9 |

32.0 |

31.6 |

2970 |

|

4×70* |

19/2.14 |

1.1 |

1.2 |

2.0 |

2.1 |

37.7 |

36.9 |

4240 |

|

4×95* |

19/2.52 |

1.1 |

1.2 |

2.0 |

2.2 |

41.7 |

40.9 |

5400 |

|

4×120* |

37/2.03 |

1.2 |

1.4 |

2.5 |

2.3 |

47.1 |

45.9 |

7000 |

|

4×150* |

37/2.25 |

1.4 |

1.4 |

2.5 |

2.4 |

51.4 |

50.2 |

8350 |

|

4×185* |

37/2.52 |

1.6 |

1.4 |

2.5 |

2.6 |

56.6 |

55.4 |

10130 |

|

4×240* |

61/2.25 |

1.7 |

1.6 |

2.5 |

2.7 |

63.0 |

61.4 |

12840 |

|

4×300* |

61/2.52 |

1.8 |

1.6 |

2.5 |

2.9 |

68.8 |

67.2 |

15530 |

|

4×400* |

61/2.85 |

2 |

1.8 |

3.15 |

3.2 |

78.1 |

76.1 |

19950 |

* Shaped stranded conductor (class 2)

Four-core 600/1000 V cables with solid aluminum conductors

|

Nominal Cross-sectional Area |

Nominal Insulation thickness |

Nominal Bedding thickness |

Nominal Steel Wire Armor dia. |

Armour strip |

Nominal Sheath thickness |

Approx. Overall Diameter |

Aprrox |

|||

|

thick-ness |

width |

wire armor |

strip armor |

|||||||

|

Extruded bedding |

Taped bedding |

|||||||||

|

mm² |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

4×16 |

0.7 |

0.8 |

1.25 |

0.6 |

2.4 |

1.6 |

21.8 |

21.8 |

20.5 |

980 |

|

4×25 |

0.9 |

1 |

1.6 |

0.6 |

2.4 |

1.7 |

26.9 |

26.5 |

24.5 |

1220 |

|

4×25* |

0.9 |

1 |

1.6 |

0.6 |

2.4 |

1.7 |

24.6 |

24.2 |

22.2 |

1220 |

|

4×35 |

0.9 |

1 |

1.6 |

0.6 |

2.4 |

1.8 |

29.5 |

29.2 |

27.1 |

1420 |

|

4×35* |

0.9 |

1 |

1.6 |

0.6 |

2.4 |

1.8 |

27 |

26.6 |

24.6 |

1420 |

|

4×50* |

1.0 |

1 |

1.6 |

1 |

2.4 |

1.9 |

30 |

29.6 |

28.4 |

1770 |

|

4×70* |

1.1 |

1.2 |

2.0 |

1 |

3.6 |

2.1 |

35.3 |

34.5 |

32.5 |

2500 |

|

4×95* |

1.1 |

1.2 |

2.0 |

1.4 |

3.6 |

2.2 |

39 |

38.2 |

37 |

2980 |

|

4×120* |

1.2 |

1.4 |

2.5 |

1.4 |

4.8 |

2.3 |

44 |

42.8 |

40.6 |

3950 |

|

4×150* |

1.4 |

1.4 |

2.5 |

1.4 |

4.8 |

2.4 |

47.9 |

46.7 |

44.5 |

4600 |

|

4×185* |

1.6 |

1.4 |

2.5 |

1.4 |

4.8 |

2.6 |

52.7 |

51.5 |

49.3 |

5430 |

|

4×240* |

1.7 |

1.6 |

2.5 |

1.8 |

4.8 |

2.7 |

58.5 |

56.9 |

55.5 |

6660 |

|

4×300* |

1.8 |

1.6 |

2.5 |

1.8 |

6.4 |

2.9 |

63.8 |

62.2 |

60.8 |

7770 |

*Solid shaped conductor (class 1)

Five-core 600/1000 V cables with stranded copper conductors

|

Nominal Cross-sectional Area |

Strand Type |

Nominal Insulation thickness |

Nominal Bedding thickness |

Nominal Steel Wire Armor dia. |

Nominal Sheath thickness |

Approx. Overall Diameter |

Aprrox |

|

|

Extruded bedding |

Taped bedding |

|||||||

|

mm² |

No./mm |

mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

5×1.5 |

7/0.53 |

0.6 |

0.8 |

0.9 |

1.4 |

14.3 |

– |

430 |

|

5×2.5 |

7/0.67 |

0.7 |

0.8 |

0.9 |

1.4 |

16.1 |

– |

545 |

|

5×4 |

7/0.85 |

0.7 |

0.8 |

0.9 |

1.5 |

17.8 |

– |

680 |

|

5×6 |

7/1.04 |

0.7 |

0.8 |

1.25 |

1.5 |

20 |

– |

840 |

|

5×10 |

7/1.35 |

0.7 |

0.8 |

1.25 |

1.6 |

22.9 |

– |

1105 |

|

5×16 |

7/1.70 |

0.7 |

1 |

1.6 |

1.7 |

26.6 |

26.2 |

1450 |

|

5×25 |

7/2.14 |

0.9 |

1 |

1.6 |

1.8 |

31.5 |

31.1 |

2245 |

|

5×35 |

7/2.52 |

0.9 |

1 |

1.6 |

1.9 |

34.8 |

34.4 |

2840 |

|

5×50 |

19/1.78 |

1.0 |

1.2 |

2 |

2 |

40.4 |

39.6 |

3895 |

|

5×70 |

19/2.14 |

1.1 |

1.2 |

2 |

2.2 |

46.3 |

45.5 |

5145 |

Multi-core 600/1000 V cables with stranded copper conductors

|

Nominal Cross-sectional Area |

Strand Type |

Nominal Insulation thickness |

Nominal Bedding thickness |

Nominal Steel Wire Armor dia. |

Nominal Sheath thickness |

Approx.Overall Diameter |

Aprrox Weight |

|

mm² |

No./mm |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

7×1.5 |

7/0.53 |

0.6 |

0.8 |

0.9 |

1.4 |

15.2 |

500 |

|

12×1.5 |

7/0.53 |

0.6 |

0.8 |

1.25 |

1.5 |

19.4 |

820 |

|

19×1.5 |

7/0.53 |

0.6 |

0.8 |

1.25 |

1.6 |

22.2 |

1080 |

|

27×1.5 |

7/0.53 |

0.6 |

1 |

1.6 |

1.7 |

26.7 |

1550 |

|

37×1.5 |

7/0.53 |

0.6 |

1 |

1.6 |

1.7 |

29 |

1850 |

|

48×1.5 |

7/0.53 |

0.6 |

1 |

1.6 |

1.8 |

32.7 |

2250 |

|

7×2.5 |

7/0.67 |

0.7 |

0.8 |

0.9 |

1.4 |

17.1 |

730 |

|

12×2.5 |

7/0.67 |

0.7 |

0.8 |

1.25 |

1.6 |

22.4 |

1020 |

|

19×2.5 |

7/0.67 |

0.7 |

1 |

1.6 |

1.7 |

26.6 |

1530 |

|

27×2.5 |

7/0.67 |

0.7 |

1 |

1.6 |

1.8 |

30.7 |

1960 |

|

37×2.5 |

7/0.67 |

0.7 |

1 |

1.6 |

1.8 |

33.8 |

2450 |

|

48×2.5 |

7/0.67 |

0.7 |

1.2 |

2 |

2 |

39.3 |

3260 |

|

7×4 |

7/0.85 |

0.7 |

0.8 |

1.25 |

1.5 |

19.7 |

840 |

|

12×4 |

7/0.85 |

0.7 |

1 |

1.6 |

1.6 |

25.7 |

1390 |

|

19×4 |

7/0.85 |

0.7 |

1 |

1.6 |

1.7 |

29.3 |

1850 |

|

27×4 |

7/0.85 |

0.7 |

1 |

1.6 |

1.9 |

34.4 |

2350 |

|

37×4 |

7/0.85 |

0.7 |

1.2 |

2 |

2 |

39.2 |

2800 |

|

48×4 |

7/0.85 |

0.7 |

1.2 |

2 |

2.1 |

44.1 |

3250 |