LOW VOLTAGE POWER CABLES WITH (PVC, PE and XLPE, HFFR) INSULATION

NYY, NAYY, NYBY, NAYBY, NYCY, NAYCY, NYCWY, NAYCWY, NYRY, NAYRY, NY2Y, NAY2Y (E-AY2Y), N2XY, NA2XY; N2X2Y, NA2X2Y, N2XYRY, NA2XYRY

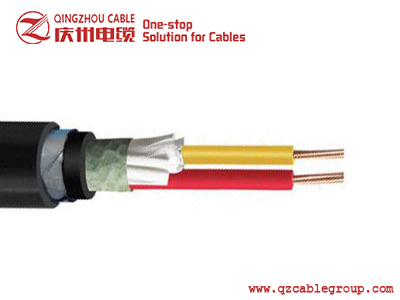

NYY, NAYY

Power cable with PVC insulation and PVC sheath

Rated Voltage: U0/U – 0.6/1 kV

Standard: DIN VDE 0276/HD603 type 3G-2-power; DIN VDE 0276/HD627 type 4H1 – signal

Application

NYY, NAYY is used in power plants industrial and switching installations in secondary distribution networks and other These cables are preferentially used in outdoor applications for indoor installations in the open air underground and in water where mechanical damage is not anticipated.

|

Technical Data: |

Cable Structure: |

||

|

Conductor resistance at 20oC: |

according to VDE 0295 and IEC 60228 |

Conductor: |

solid or multi-strand Cu or Al wires class 1, 2 or 5 acc. VDE 0295(IEC 60228) |

|

Core temperature, max: |

70oC in operation |

||

|

Max. short circuit temperature: |

160 oC , not more than 5 sec |

Insulation: |

PVC type DIV4 acc. VDE0207 |

|

Rated voltage – U0 /U (Umax): |

0.6/1(1.2) kV |

Core identification: |

according to VDE 0293 |

|

Test voltage: |

AC – 4 kV; 50 Hz |

Signal-command copper core: |

Additional, cross section 2,5mm2, red coloured (black coloured 1,5mm2 on request) |

|

Temperature Range |

|

||

|

Cores assembly: |

cores stranded concentrically (cores stranded in concentric layers, for signal) |

||

|

Fixed installation: |

-30°C to +70°C |

||

|

Flexible Installation: |

-5°C to +50°C |

Inner sheath: |

rubber filling compound or tape |

|

Bending radius, min. |

|

Sheath: |

PVC type DMV5 acc. VDE 0207 |

|

single core: |

15xDcable |

Color of sheath: |

black |

|

multi core: |

12xDcable |

|

|

|

Specific insulation resistance at 70°C: |

min, 1010 Ωx cm |

||

|

Max. permessible tensile stress with cable grip: |

For Cu conducor = 50 N/mm2 |

||

|

For Al conducor = 30 N/mm2 |

|||

|

Construction data: NYY U0/U – 0.6/1kV |

|||||

|

Number of cores x Nominal Cross Section |

Shape

|

Overall Diameter (Approx.) |

Copper weight (Approx.) |

Total Weight (Approx.) |

Packing: Cable coil or Drum |

|

No x mm² |

|

max.mm |

kg/km |

kg/km |

m or N°/m |

|

1×4 |

RE |

8,0 |

38,0 |

104,0 |

100 |

|

1×6 |

RE |

9,0 |

58,0 |

128,0 |

100 |

|

1×10 |

RE |

10,0 |

96,0 |

176,0 |

100 |

|

1×16 |

RE |

11,0 |

154,0 |

239,0 |

9/1000 |

|

1×25 |

RM |

13,0 |

240,0 |

380,0 |

9/1000 |

|

1×35 |

RM |

14,0 |

336,0 |

477,0 |

10/1000 |

|

1×50 |

RM |

15,0 |

480,0 |

650,0 |

10/1000 |

|

1×70 |

RM |

17,0 |

672,0 |

864,0 |

12/1000 |

|

1×95 |

RM |

19,0 |

912,0 |

1132,0 |

12/1000 |

|

1×120 |

RM |

21,0 |

1150,0 |

1405,0 |

14/1000 |

|

1×150 |

RM |

22,0 |

1440,0 |

1710,0 |

14/1000 |

|

1×185 |

RM |

24,0 |

1776,0 |

2086,0 |

14/1000 |

|

1×240 |

RM |

27,0 |

2304,0 |

2669,0 |

16/1000 |

|

1×300 |

RM |

30,0 |

2880,0 |

3305,0 |

16/1000 |

|

1×400 |

RM |

34,0 |

3840,0 |

4337,0 |

18/1000 |

|

3×1.5 |

RE |

12,0 |

43,0 |

223,0 |

9/1000 |

|

3×2.5 |

RE |

13,0 |

72,0 |

272,0 |

9/1000 |

|

3×4 |

RE |

15,0 |

115,0 |

373,0 |

10/1000 |

|

3×6 |

RE |

16,0 |

173,0 |

466,0 |

12/1000 |

|

3×10 |

RE |

18,0 |

288,0 |

629,0 |

12/1000 |

|

3×16 |

RE |

20,0 |

461,0 |

850,0 |

12/1000 |

|

3×25/16 |

RM /RM |

25,0 |

874,0 |

1595,0 |

14/1000 |

|

3×35/16 |

SM /RM |

27,0 |

1162,0 |

1718,0 |

16/1000 |

|

3×50/25 |

SM /RM |

30,5 |

1680,0 |

2383,0 |

14/500 |

|

3×70/35 |

SM /SM |

33,0 |

2352,0 |

3196,0 |

14/500 |

|

3×95/50 |

SM /SM |

38,0 |

3216,0 |

4271,0 |

16/500 |

|

3×120/70 |

SM /SM |

41,0 |

4128,0 |

5281,0 |

16/500 |

|

3×150/70 |

SM /SM |

45,5 |

4992,0 |

6408,0 |

18/500 |

|

3×185/95 |

SM /SM |

50,0 |

6240,0 |

7909,0 |

20/500 |

|

3×240/120 |

SM /SM |

57,0 |

8064,0 |

10162,0 |

22/500 |

|

4×1.5 |

RE |

13,0 |

58,0 |

256,0 |

9/1000 |

|

4×2.5 |

RE |

14,0 |

96,0 |

316,0 |

10/1000 |

|

4×4 |

RE |

15,0 |

154,0 |

439,0 |

10/1000 |

|

4×6 |

RE |

17,0 |

230,0 |

547,0 |

12/1000 |

|

4×10 |

RE |

19,0 |

384,0 |

743,0 |

12/1000 |

|

4×16 |

RE |

22,0 |

614,0 |

1039,0 |

14/1000 |

|

4×25 |

RM |

26,5 |

960,0 |

1620,0 |

16/1000 |

|

4×35 |

SM |

27,0 |

1344,0 |

1916,0 |

16/1000 |

|

4×50 |

SM |

31,0 |

1920,0 |

2639,0 |

14/500 |

|

4×70 |

SM |

35,0 |

2688,0 |

3576,0 |

14/500 |

|

4×95 |

SM |

40,0 |

3648,0 |

4746,0 |

16/500 |

|

4×120 |

SM |

43,0 |

4608,0 |

5813,0 |

16/500 |

|

4×150 |

SM |

48,0 |

5760,0 |

7263,0 |

18/500 |

|

4×185 |

SM |

53,0 |

7104,0 |

8905,0 |

20/500 |

|

4×240 |

SM |

60,0 |

9210,0 |

11430,0 |

24/500 |

|

5×1.5 |

RE |

14,0 |

72,0 |

292,0 |

10/1000 |

|

5×2.5 |

RE |

15,0 |

120,0 |

363,0 |

10/1000 |

|

5×4 |

RE |

17,0 |

192,0 |

510,0 |

12/1000 |

|

5×6 |

RE |

18,5 |

288,0 |

640,0 |

12/1000 |

|

5×10 |

RE |

21,0 |

480,0 |

899,0 |

14/1000 |

|

5×16 |

RE |

23,0 |

768,0 |

1240,0 |

14/1000 |

|

5×25 |

RM |

30,0 |

1200,0 |

1957,0 |

16/1000 |

|

7×1.5 |

RE |

15,0 |

101,0 |

350,0 |

10/1000 |

|

10×1.5 |

RE |

17.5 |

144,0 |

476,0 |

12/1000 |

|

12×1.5 |

RE |

18,0 |

173,0 |

523,0 |

12/1000 |

|

14×1.5 |

RE |

18,7 |

202,0 |

578,0 |

12/1000 |

|

19×1.5 |

RE |

20,5 |

274,0 |

716,0 |

14/1000 |

|

|

|

|

|

|

|

|

24×1.5 |

R E |

23,5 |

346,0 |

885,0 |

14/1000 |

|

30×1.5 |

R E |

25,0 |

432,0 |

1045,0 |

14/1000 |

|

40×1.5 |

R E |

27,0 |

576,0 |

1310,0 |

16/1000 |

|

7×2.5 |

R E |

16,0 |

168,0 |

445,0 |

12/1000 |

|

10×2.5 |

R E |

19,0 |

240,0 |

610,0 |

12/1000 |

|

12×2.5 |

R E |

19,5 |

288,0 |

680,0 |

12/1000 |

|

14×2.5 |

R E |

20,5 |

336,0 |

755,0 |

14/1000 |

|

19×2.5 |

R E |

22,5 |

456,0 |

950,0 |

14/1000 |

|

24×2.5 |

R E |

26,0 |

576,0 |

1173,0 |

16/1000 |

|

30×2.5 |

R E |

27,2 |

720,0 |

1398,0 |

16/1000 |

|

40×2.5 |

R E |

30,0 |

960,0 |

1778,0 |

16/1000 |

|

Construction data : NAYY U0/U- 0. 6/ 1k V |

|||||

|

Number of cores x No. m ina l Cross Section |

Sh a p e |

Overall Diameter (A p p r o x.) |

Al. weigh t (A p p r o x.) |

To ta l Weight (A p p r o x.) |

Pa c kin g: Cable Coil o r Drum |

|

N o x mm² |

|

ma x. mm |

kg / km |

kg / km |

m o r N ° / m |

|

4x 25+1. 5 |

R M +R E |

27, 5 |

290, 0 |

1081, 0 |

12/ 500 |

|

4x 35+1. 5 |

R M +R E |

30, 0 |

406, 0 |

1293, 5 |

14/ 500 |

|

4x 50+1. 5 |

S M +R E |

31, 0 |

580, 0 |

1340, 0 |

14/ 500 |

|

4x 70+1. 5 |

S M +R E |

35, 0 |

812, 0 |

1755, 0 |

16/ 500 |

|

4x 95+1. 5 |

S M +R E |

40, 0 |

1102, 0 |

2262, 0 |

16/ 500 |

|

4x 120+1. 5 |

S M +R E |

43, 0 |

1392, 0 |

2702, 0 |

16/ 500 |

|

4x 150+1. 5 |

S M +R E |

48, 0 |

1740, 0 |

3370, 5 |

18/ 500 |

|

4x 185+1. 5 |

S M +R E |

53, 0 |

2146, 0 |

4086, 5 |

20/ 500 |

|

4x 240+1. 5 |

S M +R E |

59, 0 |

2784, 0 |

5142, 0 |

22/ 500 |

NYBY, NAYBY

Power Cable PVC insulated and armoured with two steel tapes

Rated Voltage: U0/U – 0.6/1 kV Standard: IEC 60502-1(DIN VDE 0271)

Application

NYBY is used in power plants, industrial and switching installations, for street lighting, domestic power supply connections, in secondary distribution networks and other. These cables are also used as control cables for transmission of measured values control and regulation pulses. These cables are preferentially used for underground application as well as for interior installation in room and cable ducts and for outdoor and applications, for indoor installations, in the open air, underground and in wet ambient where greater mechanical protection an protection against accidental contact is required if damaged.

|

Technical Data: |

Cable Structure: |

||

|

Conductor resistance at 20oC: |

according to VDE 0295 and IEC 60228 |

Conductor: |

solid or multi-strand Cu or Al wires |

|

Core temperature, max: |

70oC in operation |

class 1, 2 or 5 acc. VDE 0295(IEC 60228) |

|

|

Max. short circuit temperature: |

160 oC , not more than 5 sec |

Insulation: |

PVC acc. to IEC 60502 |

|

Rated voltage – U0 /U (Umax): |

0.6/1 (1.2) kV |

Core identification: |

single core-black, multiple core |

|

Test voltage: |

AC – 3.5 kV; 50 Hz |

according to VDE 0293 (HD 308) |

|

|

Temperature Range |

|

Cores assembly: |

cores stranded concentrically |

|

Fixed installation: |

-30°C to +70°C |

(cores stranded in concentric layers, for signal) |

|

|

Flexible Installation: |

-5°C to +50°C |

Inner sheath: |

PVC filling compound |

|

Bending radius, min. |

|

Armour: |

|

|

single core: |

15xDcable |

for multi-core cable: |

two steel tapes |

|

multi core: |

12xDcable |

for single-core cable: |

two Aluminium tapes |

|

Specific insulation resistance at 70°C: |

min. 1010Ώxcm |

Sheat: |

PVC type ST1 acc. IEC 60502 |

|

Max. permissible tensile stress with cable grip: |

P = D2 · 3 N/mm2 D = Cable diameter (mm) |

Color: |

black |

|

Construction data: NYBY, NA YBY U 0/U – 0.6/1k V |

|||||

|

Num ber of cores x Nom inal Cross S ection |

Shape |

Overall Diam eter (Approx.) |

Copper w eight (Approx.) |

Total Weight (Approx.) |

Packing: Cable coil or Drum |

|

No x mm² |

|

max.mm |

kg/km |

kg/km |

m or N°/m |

|

NY BY |

|||||

|

2 x 1.5 |

RE |

12,4 |

29,0 |

270,0 |

9/1000 |

|

2 x 2.5 |

RE |

13,1 |

48,0 |

315,0 |

9/1000 |

|

2 x 4 |

RE |

14,9 |

77,0 |

390,0 |

10/1000 |

|

2 x 6 |

RE |

15,9 |

116,0 |

465,0 |

12/1000 |

|

2×10 |

RE |

17,5 |

192,0 |

590,0 |

12/1000 |

|

2×16 |

RM |

19,4 |

308,0 |

790,0 |

12/1000 |

|

2×25 |

RM |

24,4 |

480,0 |

1215,0 |

14/1000 |

|

|

|||||

|

3 x 1.5 |

RE |

13,0 |

43,0 |

280,0 |

9/1000 |

|

3 x 2.5 |

RE |

14,0 |

72,0 |

340,0 |

10/1000 |

|

3 x 4 |

RE |

16,0 |

115,0 |

440,0 |

12/1000 |

|

3 x 6 |

RE |

17,0 |

173,0 |

540,0 |

12/1000 |

|

3 x 10 |

RE |

19,0 |

288,0 |

710,0 |

12/1000 |

|

3 x 16 |

RM |

21,0 |

461,0 |

970,0 |

12/1000 |

|

|

|||||

|

3×25/16 |

RM/RE |

28,0 |

874,0 |

1740,0 |

12/500 |

|

3×35/16 |

RM/RE |

32,0 |

1162,0 |

2340,0 |

14/500 |

|

3×50/25 |

S M/RM |

33,0 |

1680,0 |

2765,0 |

14/500 |

|

3×70/35 |

S M/S M |

36,0 |

2352,0 |

3590,0 |

14/500 |

|

3×95/50 |

S M/S M |

41,0 |

3216,0 |

4700,0 |

16/500 |

|

3×120/70 |

S M/S M |

43,0 |

4128,0 |

5720,0 |

16/500 |

|

3×150/70 |

S M/S M |

49,0 |

4992,0 |

6880,0 |

18/500 |

|

3×185/95 |

S M/S M |

53,0 |

6240,0 |

8440,0 |

20/500 |

|

3×240/120 |

S M/S M |

60,0 |

8064,0 |

10880,0 |

22/500 |

|

|

|||||

|

4×1.5 |

RE |

14,0 |

58,0 |

313,0 |

10/1000 |

|

4×2.5 |

RE |

15,0 |

96,0 |

380,0 |

10/1000 |

|

4×4 |

RE |

17,0 |

154,0 |

520,0 |

12/1000 |

|

4×6 |

RE |

18,0 |

230,0 |

640,0 |

12/1000 |

|

4×10 |

RE |

20,0 |

384,0 |

860,0 |

14/1000 |

|

4×16 |

RM |

22,0 |

614,0 |

1170,0 |

14/1000 |

|

4×25 |

RM |

28,0 |

960,0 |

1810,0 |

12/500 |

|

4×35 |

RM |

32,0 |

1344,0 |

2630,0 |

14/500 |

|

4×50 |

S M |

33,0 |

1920,0 |

2940,0 |

14/500 |

|

4×70 |

S M |

37,0 |

2688,0 |

3860,0 |

16/500 |

|

4×95 |

S M |

42,0 |

3648,0 |

5100,0 |

16/500 |

|

4×120 |

S M |

44,0 |

4608,0 |

6150,0 |

16/500 |

|

4×150 |

S M |

49,0 |

5760,0 |

7510,0 |

18/500 |

|

4×185 |

S M |

53,0 |

7104,0 |

9170,0 |

20/500 |

|

|

|||||

|

5×1.5 |

RE |

14,5 |

72,0 |

360,0 |

10/1000 |

|

5×2.5 |

RE |

15,5 |

120,0 |

436,0 |

10/1000 |

|

5×4 |

RE |

18,0 |

192,0 |

600,0 |

12/1000 |

|

5×6 |

RE |

20,0 |

288,0 |

750,0 |

12/1000 |

|

NA YBY |

|||||

|

Number of cores x Nominal Cross Section |

Shape |

Overall Diameter (Approx.) |

Al weight (Approx.) |

Total Weight (Approx.) |

Packing: Cable coil or Drum |

|

No x mm² |

|

max.mm |

kg/km |

kg/km |

m or N°/m |

|

4×25+1.5 |

RM+RE |

28,5 |

290,0 |

1233,0 |

16/1000 |

|

4×35+1.5 |

RM+RE |

31,0 |

406,0 |

1730,0 |

18/1000 |

|

4×50+1.5 |

SM+RE |

33,0 |

580,0 |

1940,0 |

18/1000 |

|

4×70+1.5 |

SM+RE |

37,0 |

812,0 |

2310,0 |

20/1000 |

|

4×95+1.5 |

SM+RE |

42,0 |

1102,0 |

2970,0 |

16/500 |

|

4×120+1.5 |

SM+RE |

46,0 |

1392,0 |

3600,0 |

18/500 |

|

4×150+1.5 |

SM+RE |

50,0 |

1740,0 |

4230,0 |

18/500 |

|

4×185+1.5 |

SM+RE |

55,0 |

2146,0 |

5010,0 |

20/500 |

|

4×240+1.5 |

SM+RE |

61,0 |

2784,0 |

6250,0 |

24/500 |

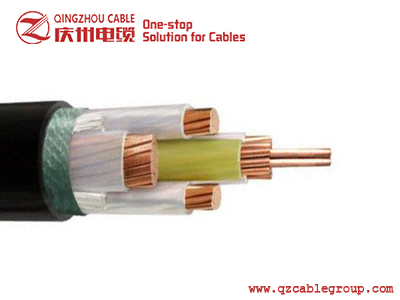

NYCY, NAYCY

Power Cable with concentric copper conductor

Rated Voltage: U0/U – 0.6/1 kV Standard:DIN VDE 0276/HD603 – power ; DIN VDE 0276/HD627 type 4H1 – signal

Application

NYCY, NAYCY is used in power plants, industrial and switching installations, for street lighting, domestic power supply connections, in secondary distribution networks and other. These cables are preferentially used for underground application as well as for interior installation in room and cable ducts and for outdoor and applications, for indoor installations, in the open air, underground and in wet ambient where greater mechanical protection and protection against accidental contact is required if damaged.

|

Technical Data: |

Cable Structure: |

||

|

Conductor resistance at 20oC: |

according to VDE 0295 and IEC 60228 |

Conductor: |

solid or multi-strand Cu or Al wires class 1, 2 or 5 acc. VDE 0295(IEC 60228) |

|

Core temperature, max: |

70oC in operation |

||

|

Max. short circuit temperature: |

160 oC , not more than 5 sec |

Insulation: |

PVC type DIV4 acc. VDE0207 |

|

Rated voltage – U0 /U (Umax): |

0.6/1(1.2) kV |

Core identification: |

according to VDE 0293 (HD 308) |

|

Test voltage: |

AC – 4 kV; 50 Hz |

Cores assembly |

cores stranded concentrically (cores stranded in concentric layers, for signal) |

|

Temperature Range |

|

||

|

Fixed installation: |

-30°C to +70°C |

Inner sheath: |

rubber filling compaund |

|

Flexible Installation: |

-5°C to +50°C |

||

|

Concentric copper conductor: |

helicoidally copper wires and one copper tape around inner covering |

||

|

Bending radius, min. |

12xDcable |

||

|

Specific insulation resistance at 70°C: |

min, 1010 Ωx cm |

||

|

Sheat: |

PVC type DMV5 acc. VDE 0207, black color |

||

|

max Permessible tensile stress with cable grip: |

For Cu conductor = 50 N/mm2 For Al conductor = 30 N/mm2 |

||

|

Construction data: NYCY U0/U – 0.6/1kV |

|||||

|

Number of cores x Nominal Cross Section |

Shape |

Overall Diameter (Approx.) |

Copper weight (Approx.) |

Total Weight (Approx.) |

Packing: Cable coil or Drum |

|

No x mm² |

|

max.mm |

kg/km |

kg/km |

m or N°/m |

|

2 x 1.5/1.5 |

RE |

14 |

60,0 |

245,0 |

10/1000 |

|

2 x 2.5/2.5 |

RE |

14 |

85,0 |

285,0 |

10/1000 |

|

2 x 4/4 |

RE |

16,0 |

125,0 |

360,0 |

12/1000 |

|

3×1.5/1.5 |

RE |

14,0 |

80,0 |

280,0 |

10/1000 |

|

3×2.5/2.5 |

RE |

15,0 |

109,0 |

316 |

10/1000 |

|

3×4/4 |

RE |

17,0 |

155,0 |

423,0 |

12/1000 |

|

3×6/6 |

RE |

18,0 |

240,0 |

530,0 |

12/1000 |

|

3×10/10 |

RE |

20,0 |

384,0 |

730,0 |

12/1000 |

|

3×16/16 |

RE |

22,0 |

610,0 |

970,0 |

14/1000 |

|

3×25/16 |

RM |

25,0 |

870,0 |

1340,0 |

14/1000 |

|

3×35/35 |

SM |

27,0 |

1340,0 |

1820,0 |

16/1000 |

|

3×50/50 |

SM |

31,0 |

1980,0 |

2490,0 |

12/500 |

|

3×70/70 |

SM |

35,0 |

2680,0 |

3350,0 |

16/500 |

|

3×95/95 |

SM |

40,0 |

3650,0 |

4490,0 |

16/500 |

|

3×120/120 |

SM |

43,0 |

4610,0 |

5500,0 |

16/500 |

|

3×150/150 |

SM |

48,0 |

5750,0 |

6950,0 |

18/500 |

|

4×1.5/1.5 |

RE |

15,0 |

94,0 |

302,0 |

10/1000 |

|

4×2.5/2.5 |

RE |

16,0 |

133,0 |

360,0 |

12/1000 |

|

4×4/4 |

RE |

18,0 |

195,0 |

485,0 |

12/1000 |

|

4×6/6 |

RE |

19,0 |

299,0 |

616,0 |

12/1000 |

|

4×10/10 |

RE |

21,0 |

480,0 |

850,0 |

14/1000 |

|

4×16/16 |

RE |

23,0 |

766,0 |

1160,0 |

14/1000 |

|

4×25/16 |

RM |

28,0 |

1112,0 |

1630,0 |

16/1000 |

|

4×35/16 |

SM |

30,0 |

1515,0 |

2080,0 |

16/1000 |

|

4×50/25 |

SM |

34,0 |

2156,0 |

2775,0 |

14/500 |

|

4×70/35 |

SM |

38,0 |

3070,0 |

3910,0 |

16/500 |

|

4×95/50 |

SM |

43,0 |

4200,0 |

5180,0 |

16/500 |

|

4×120/70 |

SM |

48,0 |

5275,0 |

6400,0 |

18/500 |

|

4×150/70 |

SM |

53,0 |

6690,0 |

8075,0 |

20/500 |

|

4×185/95 |

SM |

58,0 |

8030,0 |

9710,0 |

22/500 |

|

5×1.5/2.5 |

RE |

16,0 |

109,0 |

344,0 |

12/1000 |

|

5×2.5/2.5 |

RE |

17,0 |

158,0 |

412,0 |

12/1000 |

|

5×4/4 |

RE |

19,0 |

259,0 |

560,0 |

12/1000 |

|

5×6/6 |

RE |

20,0 |

355,0 |

690,0 |

12/1000 |

|

5×10/10 |

RE |

23,0 |

575,0 |

965,0 |

14/1000 |

|

5×16/16 |

RE |

25,0 |

940,0 |

1355,0 |

14/1000 |

|

7×1.5/2.5 |

RE |

17,0 |

141,0 |

395,0 |

12/1000 |

|

8×1.5/2.5 |

RE |

17,0 |

155,0 |

440,0 |

12/1000 |

|

10×1.5/2.5 |

RE |

20,0 |

188,0 |

510,0 |

12/1000 |

|

12×1.5/2.5 |

RE |

20,0 |

223,0 |

585,0 |

12/1000 |

|

14×1.5/2.5 |

RE |

21,0 |

253,0 |

640,0 |

14/1000 |

|

19×1.5/4 |

RE |

23,0 |

325,0 |

780,0 |

14/1000 |

|

24×1.5/6 |

RE |

26,0 |

407,0 |

950,0 |

16/1000 |

|

30×1.5/6 |

RE |

27,0 |

494,0 |

1105,0 |

16/1000 |

|

7×2.5/2.5 |

RE |

18,0 |

209,0 |

490,0 |

12/1000 |

|

8×2.5/4 |

RE |

19,0 |

233,0 |

550,0 |

12/1000 |

|

10×2.5/4 |

RE |

21,0 |

291,0 |

670,0 |

14/1000 |

|

12×2.5/4 |

RE |

22,0 |

339,0 |

730,0 |

14/1000 |

|

14×2.5/6 |

RE |

23,0 |

397,0 |

825,0 |

14/1000 |

|

19×2.5/6 |

RE |

25,0 |

516,0 |

1000,0 |

14/1000 |

|

24×2.5/10 |

RE |

28,0 |

673,0 |

1270,0 |

16/1000 |

|

30×2.5/10 |

RE |

30,0 |

820,0 |

1495,0 |

16/1000 |

NYCWY, NAYCWY

Power Cable with concentric copper conductor

Rated Voltage: U0/U – 0.6/1 kV Standard:DIN VDE 0276/HD603 type 3G-1 – power ; DIN VDE 0276/HD627 – signal

Application

Power cables for energy supply, preferably used for underground laying, especially in subscriber networks, power station as well as control impulses and test data. Overall, where increased electrical and also mechanical protection are required. These cables are installed in open air, in underground, in water, indoors and in cable ducts. The corrugated concentric conductor (CW) is allowed to use as neutral, protective or earth conductor. Simultaneously, this also is permitted to apply as a screen for example earthed-connected protection against contact. Due to the typical construction of corrugated concentric conductors (Ceander), are possible to obtain many more cable joints, without cutting any conductor. In that way the operating reliability is guaranteed.

|

Technical Data: |

Cable Structure: |

||

|

Conductor resistance at 20oC: |

according to VDE 0295 and IEC 60228 |

Conductor: |

solid or multi-strand Cu or Al wires class 1, 2 or 5 acc. VDE 0295(IEC 60228) |

|

Core temperature, max: |

70oC in operation |

||

|

Max. short circuit temperature: |

160 oC , not more than 5 sec |

Insulation: |

PVC type DIV4 acc. VDE0207 |

|

Core identification: |

according to VDE 0293 (HD 308) |

||

|

Rated voltage – U0 /U (Umax): |

0.6/1(1.2) kV |

||

|

Cores assembly: |

cores stranded concentrically (cores stranded in concentric layers, for signal) |

||

|

Test voltage: |

AC – 4 kV; 50 Hz |

||

|

Temperature Range |

|

Inner sheath: |

rubber filling compaund |

|

Fixed installation: |

-30°C to +70°C |

Concentric copper conductor: |

Waveconal outer conductor – copper wires and contrahelical copper tape (reverse lay copper tape) |

|

Flexible Installation: |

-5°C to +50°C |

||

|

Bending radius, min. |

12xDcable |

Sheath: |

PVC type DMV5 acc. VDE 0207 |

|

pecific insulation resistance at 70°C: |

min, 1010 Ωx cm |

Color: |

black |

|

ssible tensile stress with cable grip: |

For Cu conductor = 50 N/mm2 For Al conductor = 30 N/mm2 |

|

|

|

Construction data: NYCWY U0/U – 0.6/1kV |

|||||

|

Number of cores x Nominal Cross Section |

Shape |

Overall Diameter (Approx.) |

Copper weight (Approx.) |

Total Weight (Approx.) |

Packing: Cable coil or Drum |

|

No x mm² |

|

max.mm |

kg/km |

kg/km |

m or N°/m |

|

3×10/10 |

RE |

20 |

394,0 |

775,0 |

12/1000 |

|

3×16/16 |

RE |

22,0 |

630,0 |

1066,0 |

14/1000 |

|

3×25/16 |

RM |

26,0 |

895,0 |

1584,0 |

16/1000 |

|

3×35/16 |

SM |

28 |

1190,0 |

1710,0 |

16/1000 |

|

3×50/25 |

SM |

30,0 |

1722,0 |

2368,0 |

14/500 |

|

3×70/35 |

SM |

33,0 |

2411,0 |

3174 |

14/500 |

|

3×95/50 |

SM |

38,0 |

3296,0 |

4256,0 |

16/500 |

|

3×120/70 |

SM |

41,0 |

4231,0 |

5314,0 |

16/500 |

|

3×150/70 |

SM |

45,0 |

5117,0 |

6344,0 |

18/500 |

|

3×185/95 |

SM |

50,0 |

6396,0 |

8054,0 |

20/500 |

|

3×240/120 |

SM |

56,0 |

8265,0 |

10274,0 |

22/500 |

|

|

|||||

|

4×10/10 |

RE |

21,0 |

492,0 |

897,0 |

14/1000 |

|

4×16/16 |

RE |

24,0 |

787,0 |

1250,0 |

14/1000 |

|

4×25/16 |

RM |

28,0 |

1141,0 |

1822,0 |

16/1000 |

|

4×35/16 |

SM |

29,0 |

1535,0 |

2140,0 |

16/1000 |

|

4×50/25 |

SM |

33,0 |

2214,0 |

3031,0 |

14/500 |

|

4×70/35 |

SM |

38,0 |

3100,0 |

4056,0 |

16/500 |

|

4×95/50 |

SM |

43,0 |

4231,0 |

5364,0 |

16/500 |

|

4×120/70 |

SM |

46,0 |

5412,0 |

6748,0 |

18/500 |

|

4×150/70 |

SM |

51,0 |

6592,0 |

8159,0 |

20/500 |

|

4×185/95 |

SM |

57,0 |

8216,0 |

10198,0 |

22/500 |

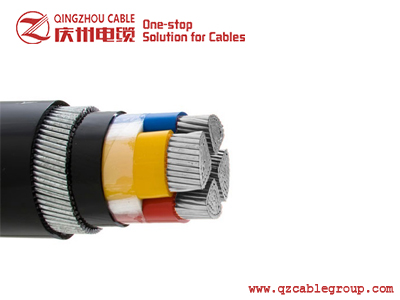

NYRY, NAYRY

Power Cable PVC insulation armored with steel wire armour

Rated Voltage: U0/U – 0.6/1 kV Standard: IEC 60502-1; DIN VDE 0271 (acc. to BS 6346)

Application

These cables are used in power plants, industrial and switching installations, for street lighting, domestic power supply connections, in secondary distribution networks and other.These cables are preferentially used for underground application as well as for interior installation in room and cableducts and for outdoor and applications, for indoor installations, in the open air, underground and in wet ambient where greater mechanical protection an protection against accidental contact is required if damaged.

|

Construct io n d a t a : N Y R Y U 0/ U – 0. 6/ 1k V |

|||||

|

Nu m b e r of c o r e s x Nom in a l C r os s S e c t ion |

Sha p e |

Ov e r a ll D iam et er ( A p p r o x . ) |

C o ppe r w e ight (A p p r o x . ) |

To ta l W e ig h t ( A ppr o x .) |

Pa c kin g: C a ble c o il or D r u m |

|

N o x mm² |

|

ma x . mm |

kg / km |

kg / km |

m o r N °/ m |

|

NY R ( A L) Y – a r m ou r w it h a lu m in iu m r oou n d w ir e s |

|||||

|

1x 10 |

R E |

14,4 |

96,0 |

326,0 |

1 0/ 1000 |

|

1x 16 |

R E |

15,4 |

154,0 |

402,0 |

1 0/ 1000 |

|

1x 25 |

R M |

17,2 |

240,0 |

541,0 |

1 2/ 1000 |

|

1x 35 |

R M |

18,3 |

336,0 |

658,0 |

1 2/ 1000 |

|

1x 50 |

R M |

20,5 |

480,0 |

841,0 |

1 2/ 1000 |

|

1x 70 |

R M |

22,5 |

672,0 |

1070,0 |

1 4/ 1000 |

|

1x 95 |

R M |

24,5 |

912,0 |

1365,0 |

1 4/ 1000 |

|

1x 120 |

R M |

26,5 |

1152,0 |

1 662,0 |

16/ 1000 |

|

1x 150 |

R M |

28,5 |

1440,0 |

1 967,0 |

16/ 1000 |

|

1x 185 |

R M |

31,0 |

1776,0 |

2 406,0 |

18/ 1000 |

|

1x 240 |

R M |

34,0 |

2304,0 |

3 071,0 |

18/ 1000 |

|

1x 300 |

R M |

38,0 |

2880,0 |

3 781,0 |

16/ 500 |

|

1x 400 |

R M |

42,0 |

3840,0 |

4 764,0 |

16/ 500 |

|

1x 500 |

R M |

46,5 |

4800,0 |

5 968,0 |

18/ 500 |

|

1x 630 |

R M |

51,0 |

6048,0 |

7 538,0 |

20/ 500 |

|

N Y R Y – a r m o u r w it h g a lv a n iz e d s t e ll w ir e s |

|||||

|

2x 1.5 |

R E |

1 4,0 |

2 8,8 |

3 47,0 |

10/ 1000 |

|

2x 2.5 |

R E |

1 5,0 |

4 8,0 |

4 03,0 |

10/ 1000 |

|

2x 4.0 |

R E |

1 6,9 |

7 6,8 |

5 16,0 |

12/ 1000 |

|

2x 6.0 |

R E |

1 8,8 |

115,2 |

701,0 |

1 2/ 1000 |

|

2x 10 |

R E |

21,0 |

192,0 |

874,0 |

1 4/ 1000 |

|

2x 16 |

R E |

23,0 |

308,0 |

1082,0 |

1 4/ 1000 |

|

2x 25 |

R M |

27,0 |

480,0 |

1565,0 |

1 6/ 1000 |

|

2x 35 |

R M |

29,0 |

672,0 |

1893,0 |

1 6/ 1000 |

|

2x 50 |

R M |

32,5 |

960,0 |

2293,0 |

1 8/ 1000 |

|

2x 70 |

R M |

37,0 |

1344,0 |

3 150,0 |

16/ 500 |

|

2x 95 |

R M |

42,0 |

1824,0 |

4 037,0 |

16/ 500 |

|

2x 120 |

R M |

45,0 |

2304,0 |

4 725,0 |

18/ 500 |

|

2x 150 |

R M |

50,5 |

2880,0 |

6 041,0 |

20/ 500 |

|

2x 185 |

R M |

55,5 |

3552,0 |

7 253,0 |

22/ 500 |

|

NYRY – a r m o u r w it h g a lv a n iz e d s t e ll w ir e s |

|||||

|

3x 1.5 |

R E |

1 4,5 |

4 3,2 |

3 82,0 |

10/ 1000 |

|

3x 2.5 |

R E |

1 5,5 |

7 2,0 |

4 48,0 |

10/ 1000 |

|

3x 4.0 |

R E |

1 8,4 |

115,2 |

678,0 |

1 2/ 1000 |

|

3x 6.0 |

R E |

1 9,6 |

172,8 |

783,0 |

1 2/ 1000 |

|

3x 10 |

R E |

22,0 |

288,0 |

1006,0 |

1 4/ 1000 |

|

3x 16 |

R E |

24,0 |

462,0 |

1276,0 |

1 4/ 1000 |

|

3x 25 |

R M |

28,0 |

720,0 |

1863,0 |

1 6/ 1000 |

|

3x 35 |

R M |

30,5 |

1008,0 |

2 279,0 |

14/ 500 |

|

3x 50 |

S M |

33,5 |

1440,0 |

2 644,0 |

14/ 500 |

|

3x 70 |

S M |

38,5 |

2016,0 |

3 664,0 |

16/ 500 |

|

3x 95 |

S M |

42,5 |

2736,0 |

4 661,0 |

16/ 500 |

|

3x 120 |

S M |

45,5 |

3456,0 |

5 478,0 |

18/ 500 |

|

3x 150 |

S M |

51,5 |

4320,0 |

7 040,0 |

20/ 500 |

|

3x 185 |

S M |

56,5 |

5328,0 |

8 457,0 |

22/ 500 |

|

3x 240 |

S M |

62,5 |

6912,0 |

10579,0 |

24/ 500 |

|

3x 300 |

S M |

68,0 |

8640,0 |

12683,0 |

24/ 500 |

|

NYRY- a r m o u r w it h g a lv a n iz e d s t e ll w ir e s |

|||||

|

4x 1.5 |

R E |

1 5,4 |

5 7,6 |

4 25,0 |

10/ 1000 |

|

4x 2.5 |

R E |

1 6,5 |

9 6,0 |

5 09,0 |

12/ 1000 |

|

4x 4.0 |

R E |

1 9,6 |

153,6 |

767,0 |

1 2/ 1000 |

|

4x 6.0 |

R E |

2 1,0 |

230,4 |

904,0 |

1 4/ 1000 |

|

4x 10 |

R E |

23,5 |

384,0 |

1179,0 |

1 4/ 1000 |

|

4x 16 |

R E |

27,0 |

616,0 |

1657,0 |

1 6/ 1000 |

|

4x 25 |

R M |

30,5 |

960,0 |

2236,0 |

1 6/ 1000 |

|

4x 35 |

R M |

33,5 |

1344,0 |

2 768,0 |

14/ 500 |

|

4x 50 |

S M |

40,0 |

1920,0 |

3639,0 |

16/ 500 |

|

4x 70 |

S M |

43,0 |

2688,0 |

4592,0 |

16/ 500 |

|

4x 95 |

S M |

50,0 |

3648,0 |

6338,0 |

20/ 500 |

|

4x 120 |

S M |

54,0 |

4608,0 |

7547,0 |

20/ 500 |

|

4x 150 |

S M |

60,5 |

5760,0 |

9073,0 |

24/ 500 |

|

4x 185 |

S M |

65,0 |

7104,0 |

10835,0 |

24/ 500 |

|

4x 240 |

S M |

72,0 |

9216,0 |

13543,0 |

24/ 450 |

|

4x 300 |

S M |

78,0 |

11520,0 |

16333,0 |

24/ 400 |

NY2Y, NAY2Y

Power Cable PVC insulation and PE sheath Rated Voltage: U0/U – 0.6/1 kV

Standard:DIN VDE 0276/HD603; IEC 60502-1

Application

Power cable suitable for laying in air, soil, water, concrete, in enclosed locations, cable ducts, in Power Plants, Industrial Applications, City Power Grids where mechanical damages are not expected and cables are not exposed to excessive pulling.

|

Construction data: NAY2Y U0/U – 0.6/1kV |

|||||

|

Nominal Cross Section |

Shape |

Overall Diameter (Approx.) |

Al weight (Approx.) |

Total Weight (Approx.) |

Packing: Cable coil or Drum |

|

No x mm² |

|

max.mm |

kg/km |

kg/km |

m or N°/m |

|

with signal wire – 2.5 mm2. |

|||||

|

4×16+2,5 |

RM+RE |

23,0 |

186,0 |

665,0 |

14/1000 |

|

4×25+2,5 |

RM+RE |

27,0 |

290,0 |

1325,0 |

16/1000 |

|

4×35+2,5 |

RM+RE |

29,0 |

406,0 |

1164,0 |

16/1000 |

|

4×50+2,5 |

SM+RE |

32,0 |

580,0 |

1290,0 |

18/1000 |

|

4×70+2,5 |

SM+RE |

36,0 |

812,0 |

1740,0 |

16/500 |

|

4×95+2,5 |

SM+RE |

40,0 |

1102,0 |

2220 |

16/500 |

|

4×120+2,5 |

SM+RE |

44,0 |

1392,0 |

2700,0 |

18/500 |

|

4×150+2,5 |

SM+RE |

49,0 |

1740,0 |

3315,0 |

20/500 |

|

4×185+2,5 |

SM+RE |

54,0 |

2146,0 |

3960,0 |

20/500 |

|

4×240+2,5 |

SM+RE |

61,0 |

2784,0 |

5065,0 |

24/500 |

|

without signal wire |

|||||

|

4×16 |

RM |

23,0 |

186,0 |

645,0 |

14/1000 |

|

4×25 |

RM |

27,0 |

290,0 |

1295,0 |

16/1000 |

|

4×35 |

RM |

29,0 |

406,0 |

1132,0 |

16/1000 |

|

4×50 |

SM |

32,0 |

580,0 |

1270,0 |

18/1000 |

|

4×70 |

SM |

36,0 |

812,0 |

1720,0 |

16/500 |

|

4×95 |

SM |

40,0 |

1102,0 |

2190,0 |

16/500 |

|

4×120 |

SM |

44,0 |

1392,0 |

2665,0 |

18/500 |

|

4×150 |

SM |

49,0 |

1740,0 |

3295,0 |

20/500 |

|

4×185 |

SM |

54,0 |

2146,0 |

3930,0 |

20/500 |

|

4×240 |

SM |

61,0 |

2784,0 |

5035,0 |

24/500 |

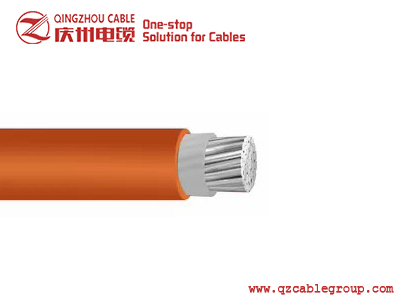

N2XY, NA2XY, N2X2Y, NA2X2Y

Power cable with XLPE insulation and PVC or PE sheath

Rated Voltage: U0/U – 0.6/1 kV Standard: VDE 0276/HD603 tip 5G-2; IEC 60502-1

Application

The power cables with insulation of cross-linked polyethylene (XLPE) are designed for distribution and supply of consumers with nominal voltage 0.6/1 kV and frequency 50 Hz in industrial installations and urban networks. They are suitable for fixed indoor assembly in cable ducts and conduits, over shelves and grilles, directly underground in ditch and outdoor under shelters providing the conditions determined for the type of cable.

|

Technical Data: |

Cable Structure: |

||

|

Conductor resistance at 20oC: |

according to VDE 0295 and IEC 60228 |

Conductor: |

solid or multi-strand Cu or Al wires class 1, 2 or (5) acc. VDE 0295 (IEC 60228) |

|

Core temperature, max: |

90oC in operation |

||

|

Max. short circuit temperature: |

250 oC , not more than 5 sec |

Insulation: |

XLPE type DIX3 acc. to VDE 0276-603/5G |

|

Rated voltage U0 /U(Umax): |

0.6/1(1.2) kV |

Core identification: |

according to VDE 0293 (HD 308) |

|

Test voltage: |

AC – 4 kV (3.5kV by IEC); 50 Hz |

||

|

Signal-command copper core: |

Additional, cross section 2,5mm2, red coloured (black coloured 1,5mm2 on request) |

||

|

Temperature range: |

|

||

|

flexing: |

-5°C to +50°C |

||

|

stationary: |

-30°C to +90°C |

Cores assembly: |

cores stranded concentrically (cores stranded in concentric layers, for signal) |

|

Bending radius, min. |

|

||

|

for single-core: |

15xDcable |

Wrapping: |

paper tape |

|

for multi-core: |

12xDcable |

Inner covering: |

rubber filling compound |

|

Specific insulation resistance at 90°C: |

min, 1014 Ωx cm |

Sheath: |

PVC type DMV6 acc. to VDE 0276-603/sec.1 or PE HDPE mass, type DMP2 acc. DIN VDE 0276/HD603 |

|

Max. permessible tensile stress with cable grip: |

For Cu conducor = 50 N/mm2 For Al conducor = 30 N/mm2 |

||

|

Color of sheath: |

black |

||

|

Construction data: N2XY U 0 / U – 0 . 6 / 1 k V |

|||||

|

N u m b e r o f c o r e s x N o m in a l C r o s s S e c t io n |

S h a p e |

O v e r a l l D ia m e t e r (A p p r o x . ) |

C o p p e r ( o r A l) w e ig h t (A p p r o x . ) |

T o t a l W e ig h t ( A p p r o x . ) |

P a c k in g : C a b le c o i l o r D r u m |

|

N o x m m ² |

|

m a x . m m |

k g / k m |

k g / k m |

m o r N ° / m |

|

1 x 4 |

R E |

6 , 5 |

3 8 , 0 |

7 4 , 0 |

1 0 0 |

|

1 x 6 |

R E |

7 , 0 |

5 8 , 0 |

9 6 , 0 |

1 0 0 |

|

1 x 1 0 |

R E |

8 , 0 |

9 6 , 0 |

1 4 2 , 0 |

1 0 0 |

|

1 x 1 6 |

R E |

9 , 0 |

1 5 4 , 0 |

2 0 5 , 0 |

8 / 1 0 0 0 |

|

1 x 2 5 |

R M |

1 1 , 0 |

2 4 0 , 0 |

3 0 2 , 0 |

9 / 1 0 0 0 |

|

1 x 3 5 |

R M |

1 2 , 0 |

3 3 6 , 0 |

4 0 0 |

9 / 1 0 0 0 |

|

1 x 5 0 |

R M |

1 3 , 0 |

4 8 0 , 0 |

5 2 6 , 0 |

9 / 1 0 0 0 |

|

1 x 7 0 |

R M |

1 6 , 0 |

6 7 2 , 0 |

7 5 0 , 0 |

1 2 / 1 0 0 0 |

|

1 x 9 5 |

R M |

1 7 , 0 |

9 1 2 , 0 |

1 0 0 0 , 0 |

1 2 / 1 0 0 0 |

|

1 x 1 2 0 |

R M |

1 8 , 5 |

1 1 5 0 , 0 |

1 2 4 0 , 0 |

1 2 / 1 0 0 0 |

|

1 x 1 5 0 |

R M |

2 1 , 0 |

1 4 4 0 , 0 |

1 5 5 0 , 0 |

1 4 / 1 0 0 0 |

|

1 x 1 8 5 |

R M |

2 3 , 0 |

1 7 7 6 , 0 |

1 8 9 0 , 0 |

1 4 / 1 0 0 0 |

|

1 x 2 4 0 |

R M |

2 6 , 0 |

2 3 0 4 , 0 |

2 4 3 0 , 0 |

1 6 / 1 0 0 0 |

|

1 x 3 0 0 |

R M |

2 8 , 0 |

2 8 8 0 , 0 |

3 0 1 5 , 0 |

1 6 / 1 0 0 0 |

|

|

|||||

|

3 x 1 . 5 |

R E |

1 0 , 0 |

4 3 , 0 |

1 4 2 , 0 |

8 / 1 0 0 0 |

|

3 x 2 . 5 |

R E |

1 1 , 0 |

7 2 , 0 |

1 8 3 , 0 |

9 / 1 0 0 0 |

|

3 x 4 |

R E |

1 2 , 0 |

1 1 5 , 0 |

2 4 2 , 0 |

9 / 1 0 0 0 |

|

3 x 6 |

R E |

1 3 , 0 |

1 7 3 , 0 |

3 2 0 , 0 |

9 / 1 0 0 0 |

|

3 x 1 0 |

R E |

1 5 , 0 |

2 8 8 , 0 |

4 8 0 , 0 |

1 0 / 1 0 0 0 |

|

3 x 1 6 |

R E |

1 7 , 0 |

4 6 1 , 0 |

7 0 0 , 0 |

1 2 / 1 0 0 0 |

|

|

|||||

|

3 x 2 5 / 1 6 |

R M / R M |

2 1 , 0 |

8 7 4 , 0 |

1 2 3 0 , 0 |

1 4 / 1 0 0 0 |

|

3 x 3 5 / 1 6 |

S M / R M |

2 6 , 0 |

1 1 6 2 , 0 |

1 4 5 0 , 0 |

1 6 / 1 0 0 0 |

|

3 x 5 0 / 2 5 |

S M / R M |

2 9 |

1 6 8 0 , 0 |

1 9 5 5 , 0 |

1 4 / 5 0 0 |

|

3 x 7 0 / 3 5 |

S M / S M |

3 1 , 0 |

2 3 5 2 , 0 |

2 7 2 0 , 0 |

1 4 / 5 0 0 |

|

3 x 9 5 / 5 0 |

S M / S M |

3 7 , 0 |

3 2 1 6 , 0 |

3 7 5 6 , 0 |

1 6 / 5 0 0 |

|

|

|||||

|

4 x 1 . 5 |

R E |

1 1 , 0 |

5 8 , 0 |

1 6 5 , 0 |

9 / 1 0 0 0 |

|

4 x 2 . 5 |

R E |

1 2 , 0 |

9 6 , 0 |

2 1 6 , 0 |

9 / 1 0 0 0 |

|

4 x 4 |

R E |

1 3 , 0 |

1 5 4 , 0 |

2 9 0 , 0 |

9 / 1 0 0 0 |

|

4 x 6 |

R E |

1 4 , 0 |

2 3 0 , 0 |

3 8 5 , 0 |

1 0 / 1 0 0 0 |

|

4 x 1 0 |

R E |

1 6 , 0 |

3 8 4 , 0 |

5 9 0 , 0 |

1 2 / 1 0 0 0 |

|

4 x 1 6 |

R E |

1 9 , 0 |

6 1 4 , 0 |

8 6 4 , 0 |

1 2 / 1 0 0 0 |

|

4 x 2 5 |

R M |

2 2 |

9 6 0 , 0 |

1 2 9 3 , 0 |

1 4 / 1 0 0 0 |

|

4 x 3 5 |

S M |

2 7 , 0 |

1 3 4 4 , 0 |

1 7 5 0 , 0 |

1 6 / 1 0 0 0 |

|

4 x 5 0 |

S M |

3 0 , 0 |

1 9 2 0 , 0 |

2 3 0 0 , 0 |

1 4 / 5 0 0 |

|

4 x 7 0 |

S M |

3 4 , 0 |

2 6 8 8 , 0 |

3 2 8 0 , 0 |

1 4 / 5 0 0 |

|

4 x 9 5 |

S M |

3 8 , 0 |

3 6 4 8 , 0 |

4 3 0 0 , 0 |

1 6 / 5 0 0 |

|

4 x 1 2 0 |

S M |

4 3 , 0 |

4 6 0 8 , 0 |

5 4 1 6 , 0 |

1 6 / 5 0 0 |

|

4 x 1 5 0 |

S M |

4 7 , 0 |

5 7 6 0 , 0 |

6 7 0 0 , 0 |

1 8 / 5 0 0 |

|

4 x 1 8 5 |

S M |

5 2 , 0 |

7 1 0 4 , 0 |

8 2 0 0 , 0 |

2 0 / 5 0 0 |

|

4 x 2 4 0 |

S M |

5 8 , 0 |

9 2 1 0 , 0 |

1 0 5 6 0 , 0 |

2 2 / 5 0 0 |

|

|

|||||

|

5 x 1 . 5 |

R E |

1 2 , 0 |

7 2 , 0 |

1 9 3 , 0 |

9 / 1 0 0 0 |

|

5 x 2 . 5 |

R E |

1 2 , 5 |

1 2 0 , 0 |

2 5 2 , 0 |

9 / 1 0 0 0 |

|

5 x 4 |

R E |

1 4 , 0 |

1 9 2 , 0 |

3 4 0 , 0 |

1 0 / 1 0 0 0 |

|

5 x 6 |

R E |

1 5 , 0 |

2 8 8 , 0 |

4 6 0 , 0 |

1 0 / 1 0 0 0 |

|

5 x 1 0 |

R E |

1 8 , 0 |

4 8 0 , 0 |

8 4 0 , 0 |

1 2 / 1 0 0 0 |

|

5 x 1 6 |

R E |

2 1 , 0 |

7 6 8 , 0 |

1 0 4 0 , 0 |

1 4 / 1 0 0 0 |

|

5 x 2 5 |

R M |

2 5 , 0 |

1 2 0 0 , 0 |

1 5 6 0 , 0 |

1 4 / 1 0 0 0 |

|

Construction data:NA2XY 0.6/1 KV |

|||||

|

4 x 1 6 + 1 . 5 |

R E + R E |

2 1 , 0 |

1 8 6 , 0 |

5 9 6 , 0 |

1 4 / 1 0 0 0 |

|

4 x 2 5 + 1 . 5 |

R M + R E |

2 4 |

2 9 0 , 0 |

8 2 0 , 0 |

1 4 / 1 0 0 0 |

|

4 x 3 5 + 1 . 5 |

R M + R E |

2 7 , 0 |

4 0 6 , 0 |

1 0 3 3 , 0 |

1 6 / 1 0 0 0 |

|

4 x 5 0 + 1 . 5 |

S M + R E |

3 0 , 0 |

5 8 0 , 0 |

1 1 3 7 , 0 |

1 4 / 5 0 0 |

|

4 x 7 0 + 1 . 5 |

S M + R E |

3 5 , 0 |

8 1 2 , 0 |

1 5 6 8 , 0 |

1 6 / 5 0 0 |

|

4 x 9 5 + 1 . 5 |

S M + R E |

3 9 , 0 |

1 1 0 2 , 0 |

1 9 4 6 , 0 |

1 6 / 5 0 0 |

|

4 x 1 2 0 + 1 . 5 |

S M + R E |

4 3 , 0 |

1 3 9 2 , 0 |

2 4 3 6 |

1 6 / 5 0 0 |

|

4 x 1 5 0 + 1 . 5 |

S M + R E |

4 7 , 0 |

1 7 4 0 , 0 |

2 9 7 3 , 0 |

1 8 / 5 0 0 |

|

4 x 1 8 5 + 1 . 5 |

S M + R E |

5 2 , 0 |

2 1 4 6 , 0 |

3 5 9 2 , 0 |

2 0 / 5 0 0 |

|

4 x 2 4 0 + 1 . 5 |

S M + R E |

5 8 , 0 |

2 7 8 4 , 0 |

4 5 7 3 , 0 |

2 2 / 5 0 0 |

|

4 x 1 6 |

R E |

2 1 , 0 |

1 8 6 , 0 |

5 7 0 , 0 |

1 4 / 1 0 0 0 |

|

4 x 2 5 |

R M |

2 4 |

2 9 0 , 0 |

7 9 4 , 0 |

1 4 / 1 0 0 0 |

|

4 x 3 5 |

S M |

2 7 , 0 |

4 0 6 , 0 |

8 7 4 , 0 |

1 6 / 1 0 0 0 |

|

4 x 5 0 |

S M |

3 0 , 0 |

5 8 0 , 0 |

1 1 1 0 , 0 |

1 4 / 5 0 0 |

|

4 x 7 0 |

S M |

3 5 , 0 |

8 1 2 , 0 |

1 5 4 0 , 0 |

1 6 / 5 0 0 |

|

4 x 9 5 |

S M |

3 9 , 0 |

1 1 0 2 , 0 |

1 9 2 0 , 0 |

1 6 / 5 0 0 |

|

4 x 1 2 0 |

S M |

4 3 , 0 |

1 3 9 2 , 0 |

2 4 1 0 , 0 |

1 6 / 5 0 0 |

|

4 x 1 5 0 |

S M |

4 7 , 0 |

1 7 4 0 , 0 |

2 9 4 6 , 0 |

1 8 / 5 0 0 |

|

4 x 1 8 5 |

S M |

5 2 , 0 |

2 1 4 6 , 0 |

3 5 6 5 , 0 |

2 0 / 5 0 0 |

|

4 x 2 4 0 |

S M |

5 8 , 0 |

2 7 8 4 , 0 |

4 5 4 5 , 0 |

2 2 / 5 0 0 |

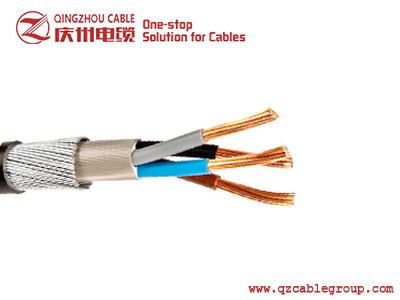

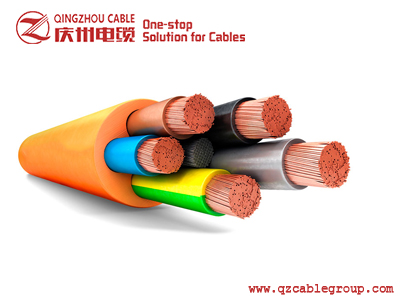

N2XYRY, NA2XYRY Power cable with XLPE insulation, steel wire armor, PVC sheath

|

C o ns t r uc t i o n d a t a : N 2X Y R Y U 0/ U – 0. 6/ 1k V |

|||||

|

Nu m b e r o f c o r e s x No m in a l C r os s S e c t ion |

Sha p e |

O v e r a ll D iam et er ( A p p r o x . ) |

C o ppe r w e ight ( A ppr o x . ) |

To t a l W e ig ht ( A ppr o x . ) |

Pa c k in g: C a ble c o il o r D r u m |

|

N o x mm² |

|

ma x . mm |

k g / k m |

k g / k m |

m o r N ° / m |

|

N 2 X Y R ( A L ) Y – a r m o ur w it h a lum inium r o o und w ir e s |

|||||

|

1x 50 |

R M |

17, 5 |

480, 0 |

742, 0 |

12/ 1000 |

|

1x 70 |

R M |

19, 0 |

672, 0 |

975, 0 |

12/ 1000 |

|

1x 95 |

R M |

21, 0 |

912, 0 |

1277, 0 |

14/ 1000 |

|

1x 120 |

R M |

23, 0 |

1152, 0 |

1547, 0 |

14/ 1000 |

|

1x 150 |

R M |

24, 5 |

1440, 0 |

1860, 0 |

14/ 1000 |

|

1x 185 |

R M |

26, 2 |

1776, 0 |

2268, 0 |

16/ 1000 |

|

1x 240 |

R M |

30, 0 |

2304, 0 |

2952, 0 |

16/ 1000 |

|

1x 300 |

R M |

32, 3 |

2880, 0 |

3434, 0 |

18/ 1000 |

|

1x 400 |

R M |

37, 0 |

3840, 0 |

4738, 0 |

20/ 1000 |

|

N 2 X Y R Y – a r m o u r w it h g a lv a n iz e d s t e ll w ir e s |

|||||

|

2x 1. 5 |

R E |

13, 0 |

28, 8 |

397, 0 |

9/ 1000 |

|

2x 2. 5 |

R E |

14, 0 |

48, 0 |

455, 0 |

10/ 1000 |

|

2x 4. 0 |

R E |

14, 5 |

76, 8 |

524, 0 |

10/ 1000 |

|

2x 6. 0 |

R E |

17, 5 |

115, 2 |

715, 0 |

12/ 1000 |

|

2x 10 |

R E |

18, 5 |

192, 0 |

869, 0 |

12/ 1000 |

|

2x 16 |

R E |

20, 5 |

307, 0 |

1102, 0 |

12/ 1000 |

|

2x 25 |

R M |

24, 5 |

480, 0 |

1637, 0 |

14/ 1000 |

|

N 2 X Y R Y – a r m o u r w it h g a lv a n iz e d s t e ll w ir e s |

|||||

|

3x 1. 5 |

R E |

13, 5 |

43, 2 |

429, 0 |

10/ 1000 |

|

3x 2. 5 |

R E |

14, 5 |

72, 0 |

498, 0 |

10/ 1000 |

|

3x 4. 0 |

R E |

15, 5 |

115, 2 |

583, 0 |

10/ 1000 |

|

3x 6. 0 |

R E |

18, 0 |

172, 8 |

800, 0 |

12/ 1000 |

|

3x 10 |

R E |

19, 5 |

288, 0 |

996, 0 |

12/ 1000 |

|

3x 16 |

R E |

21, 5 |

460, 0 |

1287, 0 |

14/ 1000 |

|

3x 25 |

R M |

25, 5 |

720, 0 |

1918, 0 |

14/ 1000 |

|

3x 35 |

R M |

30, 0 |

1008, 0 |

2602, 0 |

14/ 500 |

|

3x 50 |

S M |

31, 0 |

1440, 0 |

2771, 0 |

14/ 500 |

|

3x 70 |

S M |

35, 0 |

2016, 0 |

3826, 0 |

16/ 500 |

|

3x 95 |

S M |

38, 5 |

2736, 0 |

4849, 0 |

16/ 500 |

|

3x 120 |

S M |

42, 5 |

3456, 0 |

6158, 0 |

16/ 500 |

|

3x 150 |

S M |

47, 0 |

4320, 0 |

7356, 0 |

18/ 500 |

|

3x 185 |

S M |

51, 5 |

5328, 0 |

8914, 0 |

20/ 500 |

|

3x 240 |

S M |

57, 0 |

6912, 0 |

11082, 0 |

22/ 500 |

|

3x 300 |

S M |

62, 5 |

11520, 0 |

13366, 0 |

24/ 500 |

|

N 2 X Y R Y – a r m o u r w it h g a lv a n iz e d s t e ll w ir e s |

|||||

|

3x 25+ 16 |

R M / R M |

26, 5 |

873, 0 |

2135, 0 |

16/ 1000 |

|

3x 35+ 16 |

R M / R M |

31, 0 |

1161, 0 |

2793, 0 |

14/ 500 |

|

3x 50+ 25 |

S M / R M |

35, 5 |

1680, 0 |

3492, 0 |

16/ 500 |

|

3x 70+ 35 |

S M / S M |

38, 5 |

2352, 0 |

4414, 0 |

16/ 500 |

|

3x 95+ 50 |

S M / S M |

44, 0 |

3216, 0 |

6063, 0 |

18/ 500 |

|

3x 120+ 70 |

S M / S M |

48, 0 |

4128, 0 |

7298, 0 |

18/ 500 |

|

3x 150+ 70 |

S M / S M |

53, 0 |

4992, 0 |

8586, 0 |

22/ 500 |

|

3x 185+ 95 |

S M / S M |

58, 0 |

6240, 0 |

10409, 0 |

24/ 500 |

|

3x 240+ 120 |

S M / S M |

65, 5 |

8064, 0 |

12960, 0 |

24/ 500 |

|

3x 300+ 150 |

S M / S M |

71, 5 |

12960, 0 |

15497, 0 |

24/ 450 |

|

N 2 X Y R Y – a r m o u r w it h g a lv a n iz e d s t e ll w ir e s |

|||||

|

4x 1. 5 |

R E |

14, 0 |

57, 6 |

466, 0 |

10/ 1000 |

|

4x 2. 5 |

R E |

15, 0 |

96, 0 |

556, 0 |

10/ 1000 |

|

4x 4. 0 |

R E |

16, 0 |

153, 6 |

657, 0 |

12/ 1000 |

|

4x 6. 0 |

R E |

19, 0 |

230, 4 |

906, 0 |

12/ 1000 |

|

4x 10 |

R E |

21, 0 |

384, 0 |

1160, 0 |

14/ 1000 |

|

4x 16 |

R E |

23, 5 |

614, 0 |

1669, 0 |

14/ 1000 |

|

4x 25 |

R M |

27, 5 |

960, 0 |

2289, 0 |

16/ 1000 |

|

4x 35 |

R M |

33, 0 |

1344, 0 |

3153, 0 |

14/ 500 |

|

4x 50 |

S M |

35, 5 |

1920, 0 |

3725, 0 |

16/ 500 |

|

4x 70 |

S M |

38, 5 |

2688, 0 |

4759, 0 |

16/ 500 |

|

4x 95 |

S M |

44, 0 |

3648, 0 |

6550, 0 |

18/ 500 |

|

4x 120 |

S M |

48, 0 |

4608, 0 |

7817, 0 |

18/ 500 |

|

4x 150 |

S M |

53, 0 |

5760, 0 |

9386, 0 |

20/ 500 |

|

4x 185 |

S M |

58, 0 |

7104, 0 |

11342, 0 |

22/ 500 |

|

4x 240 |

S M |

65, 5 |

9216, 0 |

14230, 0 |

24/ 500 |

|

4x 300 |

S M |

74, 0 |

11520, 0 |

18205, 0 |

24/ 450 |

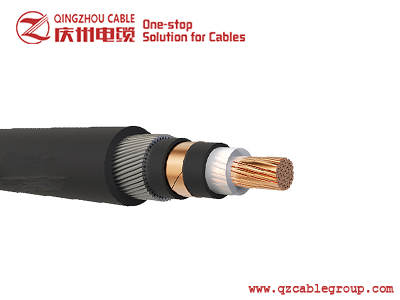

2XSY, NA2XSY, N2XS2Y, NA2XS2Y

Cu or Al single-core cables with insulation XLPE and PVC or PE sheath

Rated Voltage: U0/U – 3.6/6; 6/10; 8.7/15; 12/20; 18/30; 20/35; 20.8/36kV; Standard:VDE 0276/HD620.S2; IEC 60502-2

Application

For installation in ground, in water, outdoors, indoors and in cable ducts for power stations, industry, and distribution networks. The good installation properties of this cable make installation easy, even on difficult routes.

|

Technical Data: |

Cable Structure: |

|||

|

Conductor resistance at 20oC: |

according to VDE 0295 and IEC 60228 class 2 |

Conductor: |

Cu or Al stranded compacted, according to IEC 60228 and VDE 0295 class 2 |

|

|

Core temperature, max: |

90 °C in continuous operation |

|||

|

Max. short circuit temperature: |

250 oC , not more than 5 sec |

|||

|

Inner semi-conductive layer: |

semi-conductive XLPE compound around conductor |

|||

|

Overload temperature: |

130oC /100h per year max. |

|||

|

Highest system voltage, Umax |

3.6/6 kV = max. 7.2 kV 6/10 kV = max. 12 kV 8.7/15 kV = max. 17.5 kV 12/20 kV = max. 24 kV 18/30 kV = max. 36 kV 20/35 kV = max. 42kV 20.8/36 kV = max. 42 kV |

Insulation: |

XLPE compoundDIX8 as per DIN VDE 0276-620 part 1. |

|

|

Outer semi-conductive layer: |

semi-conductive XLPE compound around insulation |

|||

|

Warapping: |

Semi-conductive tape helicoidally wrapped |

|||

|

Metal screen: |

Cu wires concentrically laid and one contact of Cu tape with min. thickness of 0.1mm. |

|||

|

Optional metal screen: |

overlapping one or two Cu tapes |

|||

|

Test voltage = 3.5Uo(IEC60502-2); 3.5Uo(VDE 0276/HD620) AC (50Hz) – 5 min |

3.6/6 kV = 12.6 kV 6/10 kV = 21kV 8.7/15 kV = 30.45 kV 12/20 kV = 42 kV 18/30 kV = 63 kV 20/35 kV = 70kV 20.8/36 kV = 72.8 kV |

PE Sheath: |

PE compound type ST7 according to IEC 60502-2 type DMP 2 according to VDE 0276, black color |

|

|

PVC Sheath: |

PVC mass type DMV6, red (or black) coloured |

|||

|

|

||||

|

Available constructions: |

||||

|

Single Al core: |

1x(25 – 630)mm2 |

|||

|

Single Cu core: |

1x(25 – 500)mm2 |

|||

|

Level of partial discharge at 2*Uo: |

no more than 2pC |

Standard Cross section of metallic screen for conductor sizes: |

|

|

|

Bending radius, min |

15xDcable |

from 25mm2 to 120 mm2 |

16mm2 |

|

|

Temperature of laying: |

no less than – 5 oC |

|||

|

from 150mm2 to 300mm2 |

25mm2 |

|||

|

Dielectric factor of losses, 50 Hz: |

at 20°C, (0.8-3)x10-4 |

|||

|

Spec.volume insulation resistance |

at 20°C, min 1015 Ωx cm |

from 400mm2 to 630mm2 |

35mm2 |

|

|

Intensity of electric field: |

max. 6.9-5.3 kV/mm |

Standard shape of conductor RM – class 2 conductor acc. to IEC 60228 and VDE 0295 On Request: |

||

|

Tests: |

according to IEC 60502-2 or DIN VDE 0276-620 |

|||

|

Force of strain in laying, N max. |

Al cores – 30*S Cu cores – 50*S where: S is cross section of cores in mm2 |

|||

|

Construction data: N2XSY, NA2XSY |

|||||||

|

Number of cores x Nominal Cross Section |

Nominal insulation thickness |

Nominal sheath thickness |

Overall Diameter (Approx.) |

Copper weight (Approx.) |

Al weight (Approx.) |

Total Weight (Approx.) |

Packing: Cable coil or Drum |

|

No x mm² |

mm |

mm |

max.mm |

kg/km |

kg/km |

kg/km |

m or N°/m |

|

N2XSY 6/10kV |

|||||||

|

1x25RM/16 |

3.4 |

2.5 |

22.4 |

408 |

– |

800 |

14/1000 |

|

1x35RM/16 |

3.4 |

2.5 |

24.4 |

518 |

– |

960 |

14/1000 |

|

1x50RM/16 |

3.4 |

2.5 |

25 |

662 |

– |

1160 |

14/1000 |

|

1x70RM/16 |

3.4 |

2.5 |

27 |

854 |

– |

1360 |

16/1000 |

|

1x95RM/16 |

3.4 |

2.5 |

28.2 |

1094 |

– |

1600 |

16/1000 |

|

1x120RM/16 |

3.4 |

2.5 |

29.5 |

1334 |

– |

1870 |

16/1000 |

|

1x150RM/25 |

3.4 |

2.5 |

31.1 |

1723 |

– |

2270 |

16/1000 |

|

1x185RM/25 |

3.4 |

2.5 |

32.6 |

2059 |

– |

2640 |

18/1000 |

|

1x240RM/25 |

3.4 |

2.5 |

35.4 |

2587 |

– |

3210 |

20/1000 |

|

1x300RM/25 |

3.4 |

2.5 |

37.1 |

3163 |

– |

3800 |

20/1000 |

|

NA2XSY 6/10kV |

|||||||

|

1x35RM/16 |

3.4 |

2.5 |

24.4 |

182 |

101 |

700 |

14/1000 |

|

1x50RM/16 |

3.4 |

2.5 |

25 |

182 |

145 |

780 |

16/1000 |

|

1x70RM/16 |

3.4 |

2.5 |

27 |

182 |

203 |

890 |

16/1000 |

|

1x95RM/16 |

3.4 |

2.5 |

28.2 |

182 |

276 |

990 |

18/1000 |

|

1x120RM/16 |

3.4 |

2.5 |

29.5 |

182 |

348 |

1100 |

9/1000 |

|

1x150RM/25 |

3.4 |

2.5 |

31.1 |

283 |

435 |

1300 |

9/1000 |

|

1x185RM/25 |

3.4 |

2.5 |

32.6 |

283 |

537 |

1440 |

10/1000 |

|

1x240RM/25 |

3.4 |

2.5 |

35.4 |

283 |

696 |

1680 |

12/1000 |

|

1x300RM/25 |

3.4 |

2.5 |

37.1 |

283 |

870 |

1890 |

12/1000 |

|

N2XSY 12/20kV |

|||||||

|

1x35RM/16 |

5.5 |

2.5 |

27.8 |

518 |

– |

1100 |

16/1000 |

|

1x50RM/16 |

5.5 |

2.5 |

29.3 |

662 |

– |

1290 |

16/1000 |

|

1x70RM/16 |

5.5 |

2.5 |

31.2 |

854 |

– |

1540 |

18/1000 |

|

1x95RM/16 |

5.5 |

2.5 |

32.5 |

1094 |

– |

1810 |

18/1000 |

|

1x120RM/16 |

5.5 |

2.5 |

33.7 |

1334 |

– |

2080 |

18/1000 |

|

1x150RM/25 |

5.5 |

2.5 |

35.4 |

1723 |

– |

2500 |

20/1000 |

|

1x185RM/25 |

5.5 |

2.5 |

37 |

2059 |

– |

2870 |

20/1000 |

|

1x240RM/25 |

5.5 |

2.5 |

40 |

2587 |

– |

3470 |

20/1000 |

|

1x300RM/25 |

5.5 |

2.5 |

41.3 |

3163 |

– |

4080 |

22/1000 |

|

NA2XSY 12/20kV |

|||||||

|

1x35RM/16 |

5.5 |

2.5 |

27.8 |

182 |

101 |

880 |

16/1000 |

|

1x50RM/16 |

5.5 |

2.5 |

29.3 |

182 |

145 |

970 |

16/1000 |

|

1x70RM/16 |

5.5 |

2.5 |

31.2 |

182 |

203 |

1090 |

18/1000 |

|

1x95RM/16 |

5.5 |

2.5 |

32.5 |

182 |

276 |

1200 |

18/1000 |

|

1x120RM/16 |

5.5 |

2.5 |

33.7 |

182 |

348 |

1310 |

18/1000 |

|

1x150RM/25 |

5.5 |

2.5 |

35.4 |

283 |

435 |

1530 |

20/1000 |

|

1x185RM/25 |

5.5 |

2.5 |

37 |

283 |

537 |

1680 |

20/1000 |

|

1x240RM/25 |

5.5 |

2.5 |

40 |

283 |

696 |

1920 |

20/1000 |

|

1x300RM/25 |

5.5 |

2.5 |

41.3 |

283 |

870 |

2150 |

22/1000 |

|

N2XSY 20/35kV |

|||||||

|

1x35RM/16 |

9.0 |

2.5 |

34.8 |

518 |

– |

1460 |

20/1000 |

|

1x50RM/16 |

9.0 |

2.5 |

36.4 |

662 |

– |

1660 |

20/1000 |

|

1x70RM/16 |

9.0 |

2.5 |

38.2 |

854 |

– |

1930 |

20/1000 |

|

1x95RM/16 |

9.0 |

2.5 |

39.5 |

1094 |

– |

2220 |

22/1000 |

|

1x120RM/16 |

9.0 |

2.5 |

40.7 |

1334 |

– |

2500 |

22/1000 |

|

1x150RM/25 |

9.0 |

2.5 |

42.4 |

1723 |

– |

2930 |

24/1000 |

|

1x185RM/25 |

9.0 |

2.5 |

43.9 |

2059 |

– |

3310 |

24/1000 |

|

1x240RM/25 |

9.0 |

2.5 |

46.7 |

2587 |

– |

3950 |

18/500 |

|

1x300RM/25 |

9.0 |

2.5 |

48.3 |

3163 |

– |

4580 |

20/500 |

|

NA2XSY 20/35kV |

|||||||

|

1x35RM/16 |

9.0 |

2.5 |

34.8 |

182 |

101 |

1230 |

20/1000 |

|

1x50RM/16 |

9.0 |

2.5 |

36.4 |

182 |

145 |

1340 |

20/1000 |

|

1x70RM/16 |

9.0 |

2.5 |

38.2 |

182 |

203 |

1480 |

20/1000 |

|

1x95RM/16 |

9.0 |

2.5 |

39.5 |

182 |

276 |

1610 |

22/1000 |

|

1x120RM/16 |

9.0 |

2.5 |

40.7 |

182 |

348 |

1730 |

22/1000 |

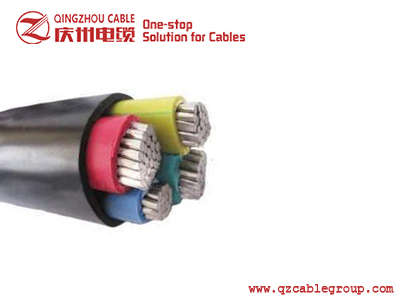

N2XSEY, NA2XSEY, N2XSE2Y, NA2XSE2Y

Cu or Al triple-core cables with insulation XLPE and PVC or PE sheath Rated Voltage: U0/U – 3.6/6; 6/10; 8.7/15; 12/20; 18/30; 20/35; 20.8/36kV;

Standard:VDE 0276/HD620.S2; IEC 60502-2

|

C onstruction da ta : N 2XSEY , NA 2XSEY |

|||||||

|

Number of cores x Nominal Cross S ection |

Nom inal insulation thickness |

Nom inal sheath thickness |

Overall Diam eter (Approx.) |

Cu w eight (Approx.) |

Al w eight (Approx.) |

Total W eight (Approx.) |

Packing: Cable coil or Drum |

|

No x mm² |

mm |

mm |

max.mm |

kg/km |

kg/km |

kg/km |

m or N°/m |

|

N2X S EY 6/10kV |

|||||||

|

3x50RM /16 |

3.4 |

2.5 |

48 |

1774 |

– |

3650 |

24/1000 |

|

3x70RM /16 |

3.4 |

2.7 |

53 |

2380 |

– |

4640 |

20/500 |

|

3x95RM /16 |

3.4 |

2.8 |

57 |

3132 |

– |

5580 |

22/500 |

|

3x120RM /16 |

3.4 |

2.9 |

60 |

3877 |

– |

6540 |

24/500 |

|

3x150RM /25 |

3.4 |

3.0 |

63 |

4768 |

– |

7720 |

24/500 |

|

3x185RM /25 |

3.4 |

3.2 |

67 |

5808 |

– |

9040 |

24/500 |

|

3x240RM /25 |

3.4 |

3.4 |

74 |

7424 |

– |

11290 |

22/250 |

|

3x300RM /25 |

3.4 |

3.4 |

77 |

9203 |

– |

13340 |

24/250 |

|

NA 2X S EY 6/10kV |

|||||||

|

3x50RM /16 |

3.4 |

2.5 |

48 |

297 |

435 |

2680 |

24/1000 |

|

3x70RM /16 |

3.4 |

2.7 |

53 |

330 |

609 |

3270 |

20/500 |

|

3x95RM /16 |

3.4 |

2.8 |

57 |

357 |

827 |

3730 |

22/500 |

|

3x120RM /16 |

3.4 |

2.9 |

60 |

378 |

1044 |

4200 |

24/500 |

|

3x150RM /25 |

3.4 |

3.0 |

63 |

406 |

1305 |

4840 |

24/500 |

|

3x185RM /25 |

3.4 |

3.2 |

67 |

428 |

1610 |

5440 |

24/500 |

|

3x240RM /25 |

3.4 |

3.4 |

74 |

474 |

2038 |

6550 |

22/250 |

|

3x300RM /25 |

3.4 |

3.4 |

77 |

502 |

2610 |

7500 |

24/250 |