High Temperature Low Sag conductors (HTLS)

High Temperature Low Sag Conductors (HTLS) can withstand higher operating temperatures of up to 210°C, thus carrying higher power compared to conventional conductors. These conductors can be applied when there is the need to use an existing Overhead Line that has clearance problems (ampacity limitations) and restrictions to use new and higher tower. HTLS conductors will allow an increase of the ampacity without the need to modify most of the existing towers.

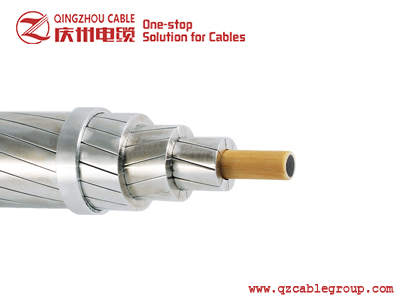

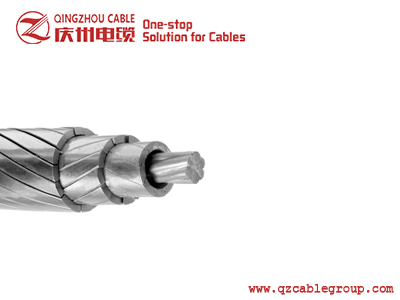

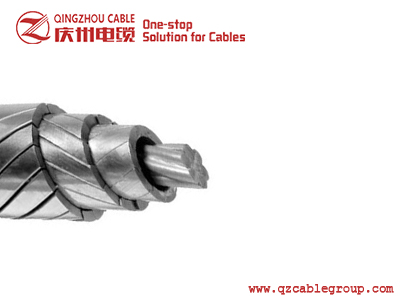

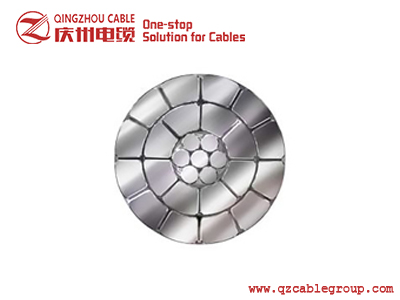

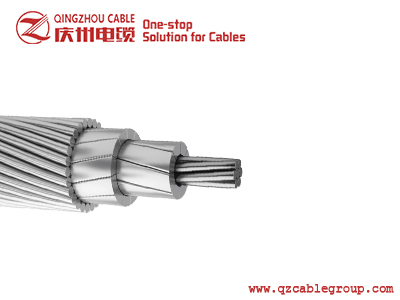

High temperature Low Sag (HTLS) conductors solve the challenges of higher temperature and higher tensile strength by using annealed aluminum or aluminum alloy conductors and a high tensile strength core which carries both the weight and the tension in the conductor span. Cores may be of metallic or composite material construction.

Low sag conductors make use of an inner core with higher tensile strength than the aluminum conductors. This allows higher tension to be applied to the conductor which allows reduced sag. Several materials have been used. Low sag conductors are designed with a centre core of a material that has a higher tensile strength than the aluminum conductor.

The six basic types of HTLS conductors are

- ZTACIR (with INVAR steel core),

- GZTACSR (with a gap between the steel core and inner layer of trapezoidal aluminum wires),

- ZTACSR (with steel core),

- ACSS (with steel core),

- Zirconium – Aluminum conductors with metal matrix composite core (for example ACCR)

- annealed aluminum conductors with organic matrix composite core (for example ACCC).

Advantages of HTLS Conductors

- Higher Current Carrying Capacity

- HTLS conductors can be operated at elevated temperatures around 150°C-250°C.

- The amount of current rating of these conductors is high compared to the conventional conductors.

- Based on the manufacturers’ information, GTACSR conductors are able to handle 1.6 times the same size ACSR while GZTACSR can handle 2.0 times the CCC of similar size ACSR conductors

- ROW saving

- HTLS conductors can be used to transfer bulk power from one stations to other, so it has the potential to reduce number of transmission lines being constructed.

- Conventional conductors are restricted to low capacities, so a requirement of multiple transmission lines is needed and hence ROW requirements will be large.

- HTLS becomes handy in such situations where they can eliminate the requirement of multiple lines by a single tower line.

- Thermal Uprating of Existing Lines

- One of the main advantages of HTLS conductors is to use them as a medium for thermal uprating of existing transmission lines.

- With the increasing demand, older transmission lines are unable to supply the required power demand and construction of new overhead lines became a challenge given the unavailability of ROW.

- Use of higher cross section line in the existing towers is not an option as the existing towers are not designed for additional forces.Even if conductors with higher cross section is used, the thermal sag of conductors will violate the required ground clearances.

- The best option is to use a suitable HTLS conductor with similar mechanical properties where:

- the existing towers can be used without violating tower safety requirements as well as minimum ground clearances.

- Energy Efficiency

- Using HTLS conductors achieves energy efficiency during power transmission.

- Conductivity of the conductors can be improved by the proper composition of elements and proper heat treatment methods.

- Energy loss (I2R) during transmission can be reduced by the use of HTLS conductors.

- This will in turn reduce the amount of power generation requirements to be met and will save fuel and CO2 .

- Long Span Crossing

- HTLS conductors can be used for longer spans crossings.

- This remained a great challenge with ACSR conductors due to its higher thermal expansion coefficient.

- At the same time, UTS (Ultimate Tensile Strength) of conventional conductors is low compared to the HTLS.With conventional conductors, taller towers are required to obtain the ground clearance.

- This also results in the need of additional steel as well as larger foundations.

- Conventional conductors cannot be tensioned to higher values as there is a risk of being subjected to fatigue failure due to wind vibration.

- With lower expansion values and higher UTS values, HTLS conductors have become a good solution for long span crossing.