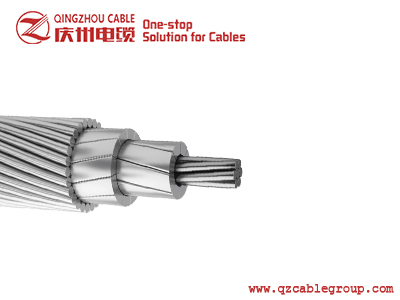

STACIR

Super Thermal Alloy Conductor Invar Reinforced (STACIR) conductor has outer layers composed of Super Thermal Aluminium (STAL) alloy wires that can operate up to 210°C (410°F). The inner core is composed of aluminium clad INVAR wires. INVAR is a metal alloy with 36% Ni in steel.

APPLICATION

STACIR/AW conductors are suited for re-conductoring applications. The capacity of existing transmission line can be enhanced by simply replacing the existing conductor without any modification to the tower.

BENEFITS

Can carry 100% more current than that of ACSR of the same size, while maximum sag and maximum working tension remain the same as that of ACSR.

No modification or reinforcement is required to existing towers for uprating transmission and distribution lines.

TECHNICAL SPECIFICATIONS

| PROPERTIES | STACIR (ACSR MOOSE EQUIVALENT) | STACIR (ACSR ZEBRA EQUIVALENT) | STACIR (ACSR PANTHER EQUIVALENT | |||

| Typical factors | 3.53 mm | 0.1390 in | 3.18 mm | 0.1252 in | 3.00 mm | 0.1181 in |

| Reference specifications | IEC 62004 | IEC 62004 | IEC 62004 | |||

| Total cross section area | 597.00 mm2 | 0.9254 in2 | 484.50 mm2 | 0.751 in2 | 261.50 mm2 | 0.4054 in2 |

| Conductive wire | Al Zr AT3 | Al Zr AT3 | Al Zr ATI | |||

| Core wire | Aluminium clad Invar | Aluminium clad Invar | Aluminium clad Invar | |||

| Conductor diameter | 31.77 mm | 1.2508 in | 28.62 mm | 1.1268 in | 21.00 mm | 0.8268 in |

| Weight | 1993 | 1339.2 | 1582 | 1063.1 | 939 | 631.0 |

| kg/gm | Ibs/mile | kg/km | Ibs/mile | kg/km | Ibs/mile | |

| Ultimate tensile strength | 14641 kg | 32277.84 lbs | 11968 kg | 26384.89 lbs | 8436 kg | 18598.17 lbs |

| DC resistance at | 0.06 | 0.09 | 0.07 | 0.11 | 0.13 | 0.21 |

| 20°C temperature | Q/km | Q/mile | Q/km | Q/mile | Q/km | Q/mile |

| Maximum operating temperature | 210°C | 410°F | 210°C | 410°F | 210°C | 410°F |

| Current carrying capacity at maximum operating temperature | 1871 Amp | 1626 Amp | 1040 Amp | |||

Assumptions: Ampacity is calculated based on, 45°C (113。F) ambient temperature, 0.6 m/s wind velocity, 0.5 as coefficient of solar absorption, 0.6 as coefficient of emmisivity and 1200 wt/sqm coefficient for solar radiation, at sea level.

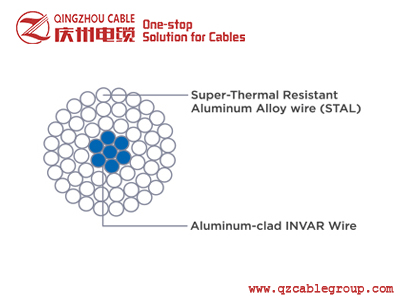

Super-Thermal Resistant Aluminum Alloy Conductors, Aluminum-clad Invar Reinforced

Application

Hi-STACIR/AW, STACIR/AW is normally used to up-rate an existing transmission line by simply replacing the exisitng conductor without tower modification or reinforcement.

Standard

IEC, ASTM, JCS 1405

Construction

Core Wire (INVAR) : Aluminum-clad INVAR Wire/High Tensile Strength Aluminum-clad INVAR Wire Conductor (STAl) : Super Thermal Resistant Aluminum Alloy Wire used for continuous allowable temperature up to 210℃

Characteristics

Double current carrying capacity of the same size ACSR No limitation for application area : Heavy wind, snow & galloping area Equivalent Sag-tension properties to conventional ACSR No modification & reinforcement on existing tower Easy installation with same method & equipments as ACSR’s Low cost and short construction period Proved long-term reliability

STACIR/AW Hi-STACIR / AW

* INVAR : INVARiable to change of temperature (a kind of Nickel-Ferrous Alloy)

STAl Wire

| Standard Diameter (mm) | Tolerance of Dia. (mm) | Tensile Strength (kgf/mm2) | Elongation on 250mm(%) Min | Reference | |||||

| Cross- sectional Area (mm2) | Weight (kg/km) | breaking Load (kgf) | DC Resistance at 20℃ (Ω/km) | ||||||

| Min. | Avg | ||||||||

| Min. | Avg (Min.) | ||||||||

| 2.6 | ±0.03 | 17.2 | 18.3 | 1.5 | 5.309 | 14.33 | 91.3 | 97.2 | 5.41 |

| 3.2 | ±0.04 | 16.5 | 17.6 | 1.7 | 8.042 | 21.71 | 133 | 142 | 3.57 |

| 3.38 | ±0.04 | 16.5 | 17.6 | 1.7 | 8.973 | 24.23 | 148 | 158 | 3.20 |

| 3.7 | ±0.04 | 16.5 | 17.2 | 1.8 | 10.75 | 29.03 | 177 | 185 | 2.67 |

| 4.0 | ±0.04 | 16.2 | 16.9 | 1.9 | 12.57 | 33.94 | 204 | 212 | 2.29 |

| 4.5 | ±0.04 | 16.2 | 16.9 | 2.0 | 15.90 | 42.93 | 258 | 269 | 1.81 |

Aluminum-clad INVAR Wire

| Standard Diameter (mm) | Tolerance of Dia. (mm) | Tensile Strength (kgf/mm2) | Elongation Min. (%) | No. of Twists (Nos.) | Conductivity (%IACS) | Properties of Aluminum | Reference | |||||||

| Thickness (mm) | Wrapping | Aluminum Thickness (mm) | Cross- sectional Area (mm2) | Weight (kg/km) | breaking Load (kgf) | Coefficient of Linear Expainsion | Modulus of Elasticity (kgf/mm2) | |||||||

| 15℃~230℃ (x10-6/℃) | 230℃~290℃ (x10-6/℃) | |||||||||||||

| 2.47 | ±0.05 | 110 | 1.5 | 20 | 14 | 0.06 | No separation between aluminum and invar core or no breakage | 0.15 | 4.790 | 34.02 | 527 | 3.7 | 10.8 | 15,500 |

| 2.6 | ±0.05 | 110 | 1.5 | 20 | 14 | 0.06 | 0.15 | 5.309 | 37.69 | 584 | 3.7 | 10.8 | 15,500 | |

| 3.1 | ±0.06 | 110 | 1.5 | 20 | 14 | 0.07 | 0.17 | 7.548 | 53.48 | 830 | 3.7 | 10.8 | 15,500 | |

| 3.2 | ±0.06 | 110 | 1.5 | 20 | 14 | 0.07 | 0.17 | 8.042 | 57.10 | 885 | 3.7 | 10.8 | 15,500 | |

| 3.38 | ±0.07 | 110 | 1.5 | 20 | 14 | 0.08 | 0.18 | 8.973 | 63.71 | 987 | 3.7 | 10.8 | 15,500 | |

| 3.5 | ±0.07 | 110 | 1.5 | 20 | 14 | 0.08 | 0.18 | 9.621 | 68.31 | 1.060 | 3.7 | 10.8 | 15,500 | |

High Tensile Strength Aluminum-clad INVAR Wire

| Standard Diameter (mm) | Tolerance of Dia. (mm) | Tensile Strength (kgf/mm2) | Elongation Min. (%) | No. of Tweists (Nos.) | Conductivity (%IACS) | Properties of Aluminum | Reference | |||||||

| Thickness (mm) | Wrapping | Aluminum Thickness (mm) | Cross- sectional Area (mm2) | Weight (kg/km) | breaking Load (kgf) | Coefficient of Linear Expainsion | Modulus of Elasticity (kgf/mm2) | |||||||

| 15℃~230℃ (x10-6/℃) | 230℃~290℃ (x10-6/℃) | |||||||||||||

| 2.47 | ±0.05 | 125 | 1.5 | 20 | 14 | 0.06 | No separation between aluminum and invar core or no breakage | 0.15 | 4.790 | 34.02 | 599 | 3.7 | 10.8 | 15,500 |

| 2.6 | ±0.05 | 120 | 1.5 | 20 | 14 | 0.06 | 0.15 | 5.309 | 37.69 | 637 | 3.7 | 10.8 | 15,500 | |

| 3.1 | ±0.06 | 120 | 1.5 | 20 | 14 | 0.07 | 0.17 | 7.548 | 53.48 | 906 | 3.7 | 10.8 | 15,500 | |

| 3.2 | ±0.06 | 120 | 1.5 | 20 | 14 | 0.07 | 0.17 | 8.042 | 57.10 | 965 | 3.7 | 10.8 | 15,500 | |

| 3.38 | ±0.07 | 120 | 1.5 | 20 | 14 | 0.08 | 0.18 | 8.973 | 63.71 | 1.077 | 3.7 | 10.8 | 15,500 | |

| 3.5 | ±0.07 | 120 | 1.5 | 20 | 14 | 0.08 | 0.18 | 9.621 | 68.31 | 1.155 | 3.7 | 10.8 | 15,500 | |

STACIR / AW

| Conductor Size (mm2) | Stranding (Nos./mm) | Min. Breaking Load (kgf) | Overall Diameter (mm) | Reference | ||||||||||

| Cross-sectional Area (mm2) | Weight (kg/km) | Modulus of Elasticity (kgf/mm2) | Coefficient of Linear Expansion (10-6/℃) | DC Resistance at 20℃ (Ω/km) | Current Carrying Capacity (A) | |||||||||

| STAl | INVAR | STAl | INVAR | Total | STAl | INVAR | Total | |||||||

| 160 | 30/2.6 | 7/2.6 | 6,140 | 18.20 | 159.30 | 37.16 | 196.46 | 441.7 | 265.2 | 706.9 | 8,040 | 16.0 | 0.1745 | 909 |

| 240 | 30/3.2 | 7/3.2 | 9,170 | 22.40 | 241.30 | 56.29 | 297.59 | 669.1 | 401.7 | 1070.8 | 8,040 | 16.0 | 0.1159 | 1,203 |

| 330 | 26/4.0 | 7/3.1 | 10,000 | 25.30 | 326.80 | 52.84 | 379.64 | 905.1 | 377.0 | 1282.1 | 7,580 | 17.5 | 0.0869 | 1,452 |

| 410 | 26/4.5 | 7/3.5 | 12,720 | 28.50 | 413.40 | 67.35 | 480.75 | 1145.5 | 480.6 | 1626.1 | 7,590 | 17.5 | 0.0686 | 1,708 |

| 480 (Rail) | 45/3.7 | 7/2.47 | 10,500 | 29.61 | 483.84 | 33.54 | 517.38 | 1340.7 | 239.3 | 1580.0 | 6,900 | 20.0 | 0.0600 | 1,812 |

| 480 (Cardinal) | 54/3.38 | 7/3.38 | 13,280 | 30.42 | 484.52 | 62.81 | 547.33 | 1343.5 | 452.2 | 1795.7 | 7,470 | 18.3 | 0.0591 | 1,846 |

Hi-STACIR/AW

| Conductor Size (mm2) | Stranding (Nos./mm) | Min. Breaking Load (kgf) | Overall Diameter (mm) | Reference | ||||||||||

| Cross-sectional Area (mm2) | Weight (kg/km) | Modulus of Elasticity (kgf/mm2) | Coefficient of Linear Expansion (10-6/℃) | DC Resistance at 20℃ (Ω/km) | Current Carrying Capacity (A) | |||||||||

| STAl | INVAR | STAl | INVAR | Total | STAl | INVAR | Total | |||||||

| 160 | 30/2.6 | 7/2.6 | 6,500 | 18.20 | 159.30 | 37.16 | 196.46 | 441.7 | 265.2 | 706.9 | 8,040 | 16.0 | 0.1745 | 909 |

| 240 | 30/3.2 | 7/3.2 | 9,700 | 22.40 | 241.30 | 56.29 | 297.59 | 669.1 | 401.7 | 1070.8 | 8,040 | 16.0 | 0.1159 | 1,203 |

| 330 | 26/4.0 | 7/3.1 | 10,500 | 25.30 | 326.80 | 52.84 | 379.64 | 905.1 | 377.0 | 1282.1 | 7,580 | 17.5 | 0.0869 | 1,452 |

| 410 | 26/4.5 | 7/3.5 | 13,300 | 28.50 | 413.40 | 67.35 | 480.75 | 1145.5 | 480.6 | 1626.1 | 7,590 | 17.5 | 0.0686 | 1,708 |

| 480 (Rail) | 45/3.7 | 7/2.47 | 11,000 | 29.61 | 483.84 | 33.54 | 517.38 | 1340.7 | 239.3 | 1580.0 | 6,900 | 20.0 | 0.0600 | 1,812 |

| 480 (Cardinal) | 54/3.38 | 7/3.38 | 13,800 | 30.42 | 484.52 | 62.81 | 547.33 | 1343.5 | 452.2 | 1795.7 | 7,470 | 18.3 | 0.0591 | 1,846 |

Comparison with Conventional ACSR

| Conductor Size (mm2) | Stranding (Nos./mm) | Weight (kg/km) | Overall Diameter (mm) | Breaking Load (kgf) | DC Resistant at 20℃ (Ω/km) | Modulus of Elasticity ① (kgf/mm2) | Coefficient of Linear Expansion ② (x10-6/℃) | Continuous Current Capacity (A) | ||

| 160 | ACSR | HAl | 30/2.6 | 732.8 | 18.2 | 6,990 | 0.182 | 9,080 | 18.0 | 454 (90℃) |

| St | 7/2.6 | |||||||||

| Hi-STACIR/AW | STAl | 30/2.6 | 706.9 | 18.2 | 6,500 | 0.1745 | 8,040 (15,500) | 16.0 (3.7) | 909 (210℃) | |

| INVAR | 7/2.6 | |||||||||

| 240 | ACSR | HAl | 30/3.2 | 1,110 | 22.4 | 10,210 | 0.139 | 9,080 | 18.0 | 593 (90℃) |

| St | 7/3.2 | |||||||||

| Hi-STACIR/AW | STAl | 30/3.2 | 1,070.8 | 22.4 | 9,700 | 0.1159 | 8,040 (15,500) | 16.0 (3.7) | 1,203 (210℃) | |

| INVAR | 7/3.2 | |||||||||

| 330 | ACSR | HAl | 26/4.0 | 1,260 | 25.3 | 10,950 | 0.0873 | 8,360 | 19.0 | 714 (90℃) |

| St | 7/3.1 | |||||||||

| Hi-STACIR/AW | STAl | 26/4.0 | 1,282.1 | 25.3 | 10,500 | 0.0869 | 7,580 (15,500) | 17.5 (3.7) | 1,452 (210℃) | |

| INVAR | 7/3.1 | |||||||||

| 410 | ACSR | HAl | 26/4.5 | 1,673 | 28.5 | 13,890 | 0.0702 | 8,360 | 19.0 | 829 (90℃) |

| St | 7/3.5 | |||||||||

| Hi-STACIR/AW | STAl | 26/4.5 | 1,626.1 | 28.5 | 13,300 | 0.0686 | 7,590 (15,500) | 17.5 (3.7) | 1,708 (210℃) | |

| INVAR | 7/3.5 | |||||||||

| 480 (Rail) | ACSR | HAl | 45/3.7 | 1,599 | 29.61 | 11,800 | 0.05994 | 7,250 | 20.8 | 891 (90℃) |

| St | 7/2.47 | |||||||||

| Hi-STACIR/AW | STAl | 45/3.7 | 1,580 | 29.61 | 11,000 | 0.0600 | 6,900 (15,500) | 20.0 (3.7) | 1,812 (210℃) | |

| INVAR | 7/2.47 | |||||||||

| 480 (Cardinal) | ACSR | HAl | 54/3.38 | 1,836 | 30.42 | 15,300 | 0.0599 | 7,990 | 19.5 | 899 (90℃) |

| St | 7/3.38 | |||||||||

| Hi-STACIR/AW | STAl | 54/3.38 | 1,795.7 | 30.42 | 13,800 | 0.0591 | 7,470 (15,500) | 18.3 (3.7) | 1,846 (210℃) | |

| INVAR | 7/3.38 | |||||||||